I don’t often start topics in the troubleshooting section lately, but I’ve learned a lot from this community just by reading others’ experiences and solutions. It’s been both fun and rewarding to give back when I can. This time, though, I’m stumped - and looking for ideas better than what I’ve managed so far on my own.

The Problem - PET-CF: A marvelous material that refuses to release

I needed a part for my car - a replacement side mirror bracket. The OEM bracket isn’t sold separately, only as part of a much more expensive assembly. Why spend $150 when a $2 printed part will do? So, with some CAD work and test fitting, I had a perfect PLA prototype.

For the final version, I used a 500g spool of PET-CF because it’s thin, strong, and extreme temp-resistant. Minor filament calibration – Flow rate and Pressure Advance and I’m off to the races (note: the TINMORRY GitHub Bambu profile is junk) I was printing beautiful parts - until I tried to remove them. That’s when the fun started, fun if you enjoy beating your head against the wall that is…![]() The material would not let go of anything!!!

The material would not let go of anything!!!

Before I waste more time - or expensive filament - I’m hoping someone here has cracked this.

What I’ve tried (no luck):

Build surfaces tested:

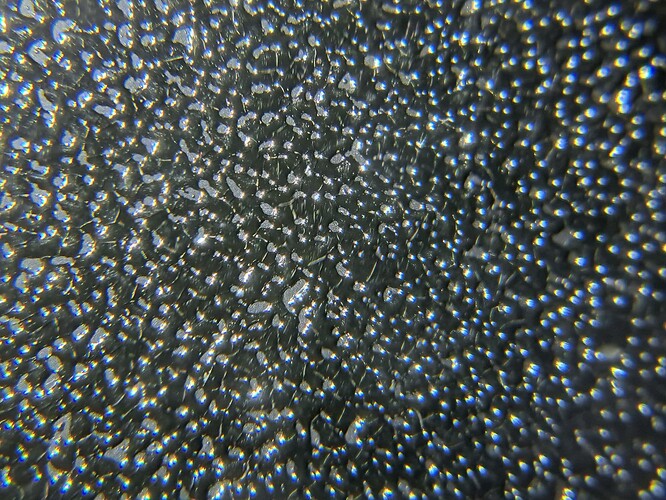

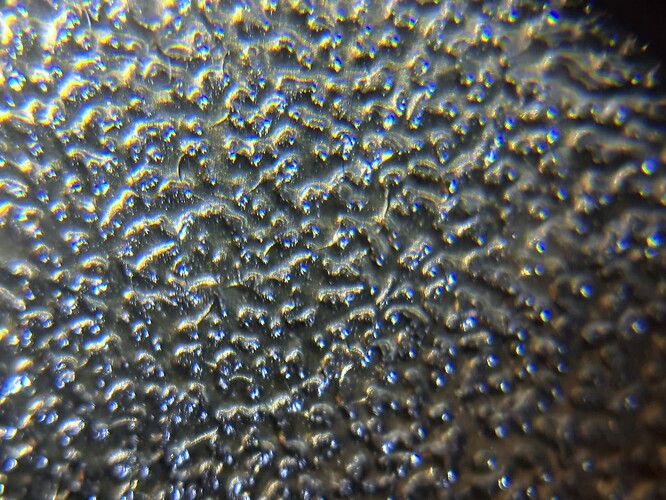

- High Temp Smooth plate

- Textured PEI

- Engineering plate with Kapton (polyimide) tape

Adhesives used as release liners:

- Bambu Liquid Adhesive

- Aqua Net hairspray

- White glue stick

- Vision Miner Nano-Polymer Adhesive - Supposed to work with PETG/PET-CF. For $45, it should print the part itself.

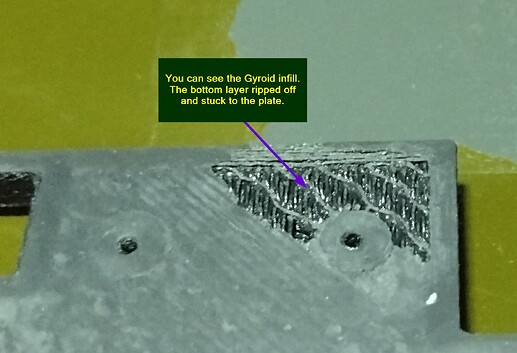

Direct-to-plate printing was a disaster. The part bonded so tightly it broke during removal.(see photo below) I since remedied that by going 100% wall thickness. Nothing to delaminate with that but it created a secondary issue in that it stuck permanently to the plate.

What I haven’t tried yet for fear of damaging my build plates:

Let me know if anyone’s tested these before I risk damaging the surface:

- Garolite G10 plate – I use this primarily for PA Nylon filament and don’t want to ruin it.

- Low tack plate (I reserve this plate for smooth finishes)

- Smooth PEI plate (likewise for the low tack plate)

What sort of worked:

- First try with Nano/adhesive, Bambu Liquid and glue stick: total failure. The part delaminated on the plate and required carving off.

- Second try: Kapton tape + tons of glue. That let me eventually peel it off - after hot water and careful razor work.

- Final method: soak in hot running water with squirts of Windex, while carefully wedge up using a razor blade and guitar pick. While it worked but I think I can do better because I can easily see there being problems with thinner models. My test strip was a 75x15x3mm cube primitive.

Looking for ideas that’ll improve on this. I’m not asking for miracles - just hoping someone has a less-destructive solution. Thanks in advance.