My printer just recently suddenly began to have moderately severe issues with bed adhesion, even on models that I have printed in the past with no issue. I’ve followed all the recommended steps to clean the print bed multiple times with no luck at all (the same cleaning techniques that have kept my printer running fine in the past), calibrated my machine multiple times, and have even flipped over my plate to the unused side. Given that this is not an issue with the cleanliness of the bed or slicer settings, what should I do to fix this, as I haven’t been able to use my printer properly for the past few days. I’d like to reiterate that this has occurred suddenly and I cannot think of a reason for this to be happening. Are there any further steps that I should take? I’m using the textured PEI plate if that makes any difference.

I hate to ask but how are you cleaning your bed?

I’m using palmolive dish soap that has no oils or moisturizers in it as per the cleaning guide with hot water, washing it like I would a normal plate. Is there a specific technique for cleaning the bed that works well for you?

Warm water and normal dish soap (cheap stuff).

- Rub well

- Rinse thoroughly

- Dry completely

During the process

- Don’t touch the surfaces

- Hold it by the edges

Depending on the ambient temperature and humidity of where the printer is located, the bed adhesion can change.

Winter vs summer can affect adhesion, as can draughts.

The supplied plate comes with two sides, are you experiencing the issues on both?

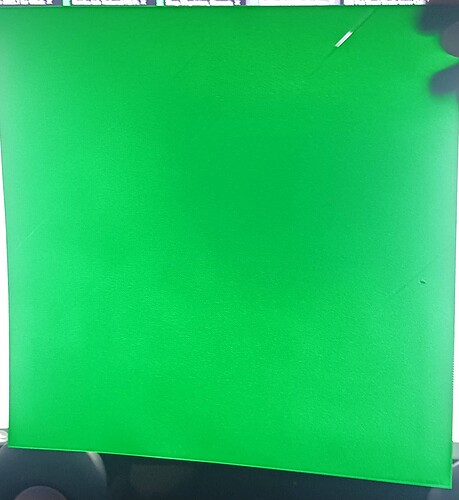

Run a test on the bed to look for issues.

This is a ready made way I made, others are available.

If the print completes with a flat sheet and no separations with a smooth and consistent surface top and bottom, dived adhesion isn’t due to the cleaning.

If you see obvious issues, clean those and try again.

If you see textures, you may have may have flow issues. Under or over extrusions.

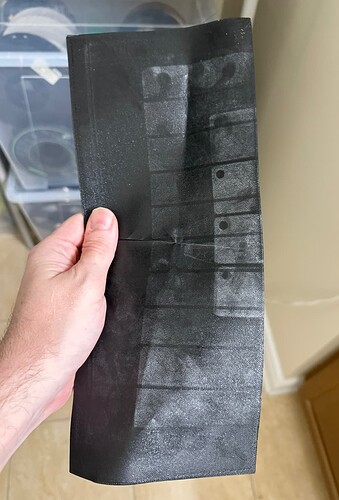

I have a new cleaning procedure for textured PEI plates. I print a full plate single layer with Soylin (Creality) black PLA. The filament is horrible to print with as it has some kind of weird additives (ripped my Geco cool plate, would not stick to Glacier at all) but those same additives make it a perfect filament for cleaning. Here is a full sheet i printed on a textured PEI plate that lost its adhesion. You can clearly see the residue of the previous prints (PLA, PA, PPS, PPA, ABS, TPU) that was lifted off. I could not clean them with water and soap, but this did the trick and restored normal adhesion on the PEI plate. The next print stuck like it was brand new.

I’m experiencing the problem on both sides, one of which is mostly unused. I’ll try the test and see what happens.

Has someone been printing lots of well positioned swatches?

Indeed, good eye! ![]()

With the new capabilities of the H2D making some PPA, PPS and other swatches for my clients.

I think this looks fine based on the pictures from the model. Do you see anything?

edit actually theres a tear in the top corner, but everywhere else looks mostly fine

Yes, that appears to be a clean print. No obvious issues showing.

Bed adhesion issues do not appear related to poor cleaning, material build up, over or under extrusion.

They can’t be rules out, but they certainly appear unlikely.