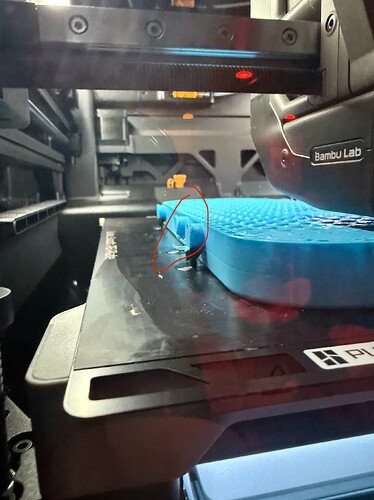

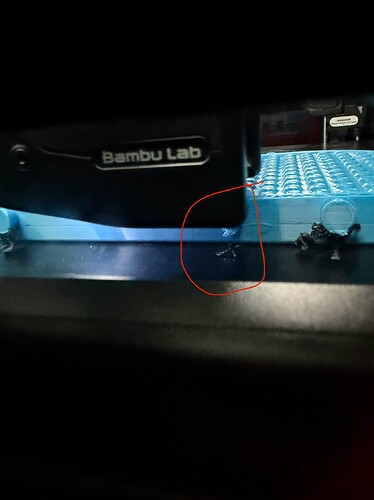

Anyone else finding their supports snapping off more often mid print on the H2D?

What material are you using for the part and what for the support?

The blue is TPU 90A and the support is pla.

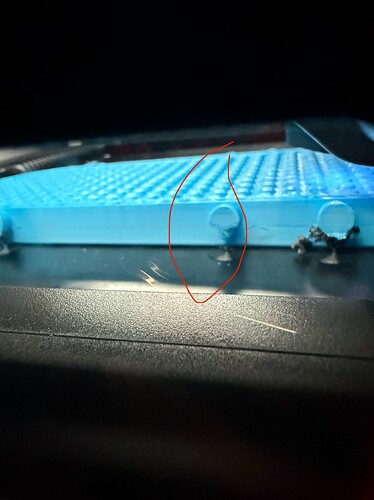

But I’ve had this happen with pla support on pla too. I feel like the printer shaking is knocking the tree support loose. Maybe I just need to use more support walls.

It’s a known issue that has been talked about a lot on the H2D. I myself have not yet experienced it because I don’t often use supports but the few models I do use supports on its been working. But i have seen there is a lot of complaints about the issue exactly as you are describing that the supports come loose around the interface area, that the print head knocks them off, etc.

In Bambu Studio 2 the way supports work was changed. It’s my guess this had to do with the H2D. Especially tree supports generate differently. Load up an older file and you will find the tree supports now are different.

So far there has not been any fix that I know of.

Thank you for that information. I have noticed the change in tree supports. Glad it’s not just me. Hopefully a slicer fix will come out soon ![]()

The reason for asking the materials is related to their bed temperatures.

One of my first PLA prints with PETG as the support interface, failed due to the bed temperature going up from 55C to 70C halfway when the first change to PETG took place.

I eventually had to tweak the bed temperature of the PETG to overcome this.

In your case probably not the issue and it’s more related to the tree supports which gave me sometimes issues also.

As @JGrimm already mentioned earlier.

You could try the standard (possibly snug) support because that gives less issues in general.

But check your bed temperature also. PLA doesn’t like a cold bed very much.

Thank you! Is that why bambu discontinued the cool plate? I loved the cool plate and used it exclusively when I first started with bambu. Never really had issues and I only used PLA.

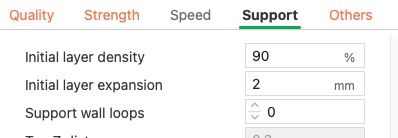

I also experienced the same issue, after I increased the Initial layer expansion from the default of 2 to 6mm and setting the Support wall loops to 2 I as able to succeed with my prints. Might give it a try and see if it helps. If nothing else, it will make it harder for them to get knocked off.

Yeah but still that’s not a real solution. I already expect the downvotes from the usual suspects, but using double supports to alleviate the disaster that Bambu made the supports into, is not a solution. What’s next? Preprinted supports that you have to preprint and then pause the normal print and install manually? Just not use supports? There’s no excuse to ACCEPT that in this oh so advanced machine, you need to make your waste in material and time double just to print successfully, if you get what I mean. I also did a workaround in numerous of my files but that’s not why I bought the h2D . It was supposed to be a tool to make my work easier and faster, not slower and more complicated for the same task as before…but don’t listen to me, the fanboys here will start talking about user errors, different parameters yada yada, when the truth is they have no clue what they are talking about. It’s a regular corexy with couple more gimmicks . If it prints flawlessly on a printer 1/10th of its price, h2D should be able to handle it similarly if not better.

I have been experiencing supports separating from the textured bed for the H2D using :

freshly opened/out of the vac bag ABS with a 0.4mm hardened steel hotend

and

freshly opened/out of the vac bag AND also out of the bag + dried with the AMS 2 Pro 8 hour cycle with basic and mattte PLA using a 0.2mm hotened.

with the 0.2mm hotend using pla matte I have been noticing the supports are breaking mid supports as well when i have default supports tree supports selected (no tweaking) + variable layer height set to highest quality.

I also started getting gaps in the supports/purge tower using the 0.2mm hotend with matte pla… I bought the H2D since I am inexperienced with 3D printers and wanted something that would give me a nice entry into the world of 3D printing but not require a massive amount of knowledge with 3D printer/FDM materials just to be able to download and print nice models off of makerworld. It is a bit frustrating having to stop failed prints many hours into the process because supports are either seperating from the bed (using glue stick as well but I have now learned about brims) or even worse because the support is breaking many layers after everything looked like it was going smoothly meanwhile their are other used commenting about how their models printed without any issues using other BambuLabs 3D printers. I also enable all the calibrations before every 3D print since the time spent before the print starts is worth not having the print fail many hours into the job.

I haven’t noticed any failed supports or support breaking with a 0.4mm hotend using PLA filament (matte and basic)

I have Bambu H2D since month now and printed few things but 2 days before I have got error message during printing and it was about 2 days printing time such as massive print job, in the middle of print tree support on this print has been broken for this reason I have complety stopped my print. another day faced troubles filaments stuck on extruder, then I have managed to clean the nozzle, but few minutes later extruder has been overloaded detected again, yesterday I have changed the blocked nozzle and continuing printing about 20hrs now, none of the problem comes up till now but I do scare about this printer and so many complain i have read. Before I upgrated to this machine I had x1c and to be honest it was the very good machine and never faced any trouble. My experience on H2D not good machine as it their price range. I will keep in eye on this machine another few weeks if any problems occured will post through bambu lab community.