I have a VERY large model I’m trying to print (37 hours). The base is round and the diameter is almost the maximum size the build plate can handle. The object needs a lot of support (total print 450g of which 150g is support). I’m using Organic tree supports which seem to give the best result in the slicer. All attempts described below used matte PLA. I also cleaned the build plate between each attempt.

Attempt 1: Got about 30 or 40 layers in and then a large portion of the support structure detached from the build plate and fell off. I had to cancel. Here I used mostly default settings but made the speed of the first layer about 50% of default.

Attempt 2: Here I added a 5 mm brim (this is the maximum I can set because of the size of the print). When printing the second layer one of the circles for one of the supports tore off and that support could no long print.

Attempt 3: Same brim and speed settings, added some adhesive on the build plate along the outside edges of the build plate where the supports print and increased the build plate temperature by 5°C for the initial layer. Same result, one of the tree bases tore off while printing the second layer.

Before I try this again does anybody have any other suggestions for settings I should change?

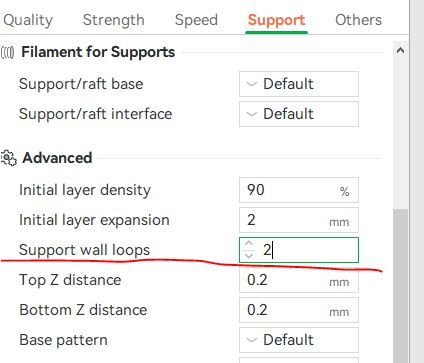

Attempt 2: Check this setting

I will try this, but I did watch the print very closely the third time and while I have that setting set to 0 which I believe means auto, it was printing two loops for each support wall.

Changing it will cause it to always print 2 loops.

Yes I realize that and I will try it. My point was that the issue of tearing the base of the tree off the build plate occured even though it was printing two walls.

really make sure the plate’s clean but

isn’t matte filament traditionally just kinda fragile? it varies depending on the brand as well.

also try drying the filament even if its pla; it helps a lot.

depending on how large the support is you could also just make a verrryy very tiny fuzzy skin set to 0.01 or something. the slight motion wiggling back and forth actually makes everything stronger and sometimes even enables you to print without support.

you might want to do a test print tho beforehand just to ensure it looks okay; most of the time when fuzzy skin is set that low its pretty smooth either way.

1 Like

Thanks for the suggestion. I’m using brand new Bambu Matte PLA. I believe it is dry. I’ve never had this issue before but I’ve never done a print where the supports are at the very edge of the print area. To me it seems like a problem on the edges of the print area, like maybe the build plate not being hot enough in the extremities to bind well. That’s why I tried increasing the initial layer build plate heat by 5°C - I had a similar issue with PETG that was solved by lowering the speed and increasing the heat. Unfortunately this didn’t help this time.

The fuzzing idea is interesting but does that setting apply to supports as well? The issue only occurs on the supports. The first layer footprint of the object itself is huge and definitely not detaching.

hmm.

if you have an ams you could print the base of the supports in an extra sticky filament such as tpu but i think i personally would give the plate a good wash with soapy water and be extra careful about not touching it.

that or get a geco plate or whatever they’re called.

might want to do a calibation, too. its possible the build plate is just slightly off and so the nozzle’s actually bumping the support off. last time that happened to me i just glued the support back onto the print and kept printing lmao.

The problem with doing a different filament for the supports is that there is nowhere for the purge block to fit.

The plate was washed and not touched between each attempts. I do this quite regularly and I have calibration turned on before each print.

I actually took the idea of gluing the support back on to another level ;). When the support got torn off it was mangled so I took a support from another print and cut it to length then I tried to glue that back in place. Unfortunately the circle size I chose was not 100% right so subsequent layers still didn’t have anywhere to build on.

I would try setting your Aux fan at 20% or below. Or even turn it off entirely. Also make sure the door is open or lid is lifted a bit.

The question is really as to what is causing the forces on the trees to detach from the base. In a scenario like the one you are describing (any pics?), I’d expect common curling to occur on the supports.

- So make sure your filament is dry (remember New = Soaked),

- keep your build chamber around 35°C (risk of heat creep but counters curling) and

- use lower layer heights (adaptive layers can be great for this).

- You may also want to play with the maximum branch angle to reduce tree overhangs.

- Finally, you may also want to consider lowering print speeds. 37h may sound like a lot. But in my experience, it is better to have a single good print in say 74h than two to three failed ones in the same time.

Saying that, for large print troubleshooting, it can help to look at particular problem features by cutting up the model and first debugging the problematic features.

&

&

1 Like

Unfortunately I didn’t take any pictures in any of my attempts. I will if it fails again.

- I believe my filament is dry so I’m ruling that out

- Are there chamber heat settings? If so I’ll definitely look at those. If not, how does one control this? Door open and aux fan like @brown_subaru suggested?

- Layer level is 0.1 IIRC

- I doubt that branch angle is the issue because this is occurring during the first couple of layers so there isn’t really a branch to speak of yet.

- Last night I learnt about the overall 50% speed control so I’ll try that today and see what happens.

Can anybody comment on whether the idea of increasing the temperature of the build plate would help?

Also does anybody know if the build plate has temperature issues around the extremities? If so, are there any tricks to compensate for that?

I really do appreciate all the help on this. Would it help if I shared the model?

Just out of curiosity: Is there a particular reason why you believe your filament to be dry?

Regarding chamber temp, my X1 tells me what it measures. For the P1, you can put a small thermo/hygrometer in the chamber (holders on MakerWorld) so you kbow when to crack open the lid.

With the layer height of .1, there’s not much room for improvement with defaults (although you can change them: I got good prints down to 0.03 with the .4 nozzle). So slowing down is the best option. Will only delay the problem though if the filament is moist.

If you have these types of defects early on, it is most likely something really basic. Like a contaminated build plate in conjunction with moist filament and crossing surfaces and infill (use monotonic and honeycomb for example).

Indeed there are cases where heating of the build plate is not uniform. Using a contactless thermometer can confirm this.

Increasing the first layer heat bed temp (+5°C) and maybe even first layer nozzle temp (+5-10°C) can help with it. Do not increase temps for subsequent layers though as that would increase the risk of elephant foot.

Sharing failure pics or even short videos and problematic models can really help troubleshooting as it really helps to avoid misunderstandings.

&

&

In the past, I had some issues with PLA detaching from a clean build plate with larger models. They would start lifting on the left side of the build plate near the aux fan. Dropping the aux fan to 20% or lower fixed that issue for me (Bambu pla default aux fan speed is 70%). If the support that keeps detaching in your model is on the left side of the plate near the aux fan, that would further support trying the lower aux fan setting.

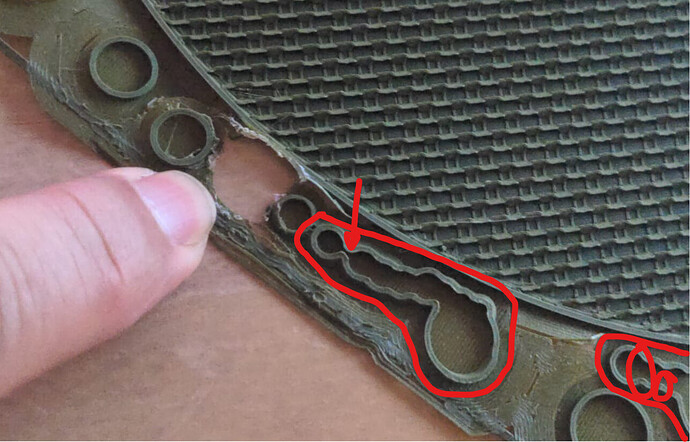

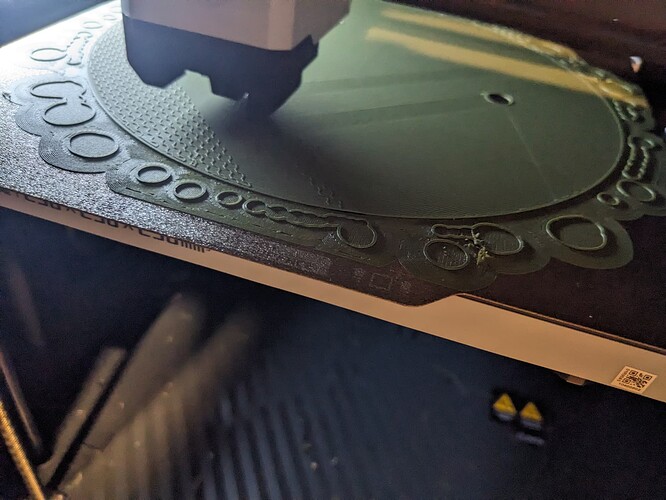

Turns out I did take a picture, unfortunately not on the build plate but you can see the problem. There is supposed to be a base of a support tree where I’m pointing. I watched the first layer get printed without issue but by the time it got to the second or third “ring” it ripped everything for that support (brim and center) off the plate.

It has only happened on the front edge of the plate. Twice to the left side of center and once to the right. Also note that all three times the support that detaches has its brim over the initial purge line. Wish there was a way to turn that off!

@EnoTheThracian I believe that my filament is dry because I have never had this issue with this same roll of filament until now but everything I have printed with it until now has been within 80mm of the center of the plate.

1 Like

That does help a lot actually. Quite a challenging print actually.

So… just wondering what I would do with this challenge and error.

I think I would first still dry my filament (again).

- Not only because I would definitely want to rule that out for good,

- but also because curling (in particular at low layer heights, within the heat bed influence) is my first indication that there’s some moisture in it.

- And there’s some obvious curling on the insides of the tree’s to the right of your finger. That kind of defect is the root cause for ripping off the trees when the nozzle collides with it. No collision => No sideways forces => no tearing out trees

- I have also had all my open rolls of filament go bad when particularly impressive thunderstorm front rolled through. It barely took 6h.

- PLA Matte is more prone to increased moisture uptake due to the increased pigmentation giving a much larger internal surface area.

But indeed, there is something else to consider. The front, in particular close to the door gap can see some drafts and hence temp drops.

- It may be worth to tape the gap closed (will not help against trees ripped out on the sides though)

- and keep the chamber warm. If you do not have much of a heat creep risk (i.e. few retracts per layer, no ironing), you can target as much as 35-39°C.

- It may also help to heat soak the printer ahead of starting a print.

- And of course, you can increase first layer heat bed temp by 5°C and 1st layer nozzle temp by 5-10°C. But it does not look like you have an actual adhesion issue (besides the purge line being in the way).

- Finally on this topic, I’d go slow! It may be painful to see longer print times, but I learned quickly that nothing is slower than having a fast print fail. Again. And again… Going slow is also a good strategy to counter curling.

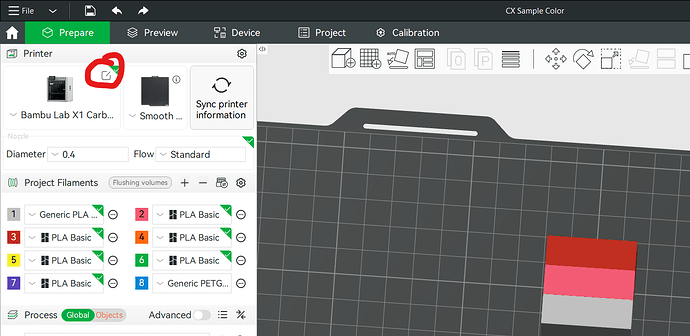

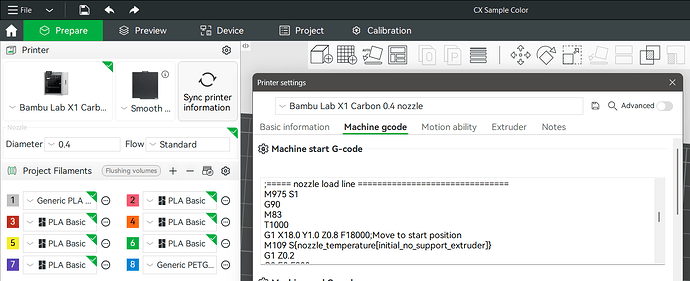

As for that pesky purge line being in the way, I do believe that you can edit it out in the Machine Start GCode. The icon comes up when you hover the mouse over your printer symbol.

Note that I have not done it myself so be extra careful if you choose to go this way and do your own research considering possible errors and consequences!!!

As my X1’s Start Gcode is a bit overloaded with the cali pattern, I am not quite certain but I believe you need to look for the code below:

;===== nozzle load line ===============================

&

&

@EnoTheThracian Thanks for taking the time to look at this. I’m doing another print now and made it to the third layer with no issues so far🤞🏼. I have the overall speed down to 50%, the aux fan down to 20%, and I figured out how to stop the prime line from printing. I think that the curling you highlighted is from me peeling that failed print off the bed in contract here is a picture of what I have right now

Actually now that I look at the picture I do see some curling on the left but it isn’t causing an issue right now. We will see how things go.

1 Like

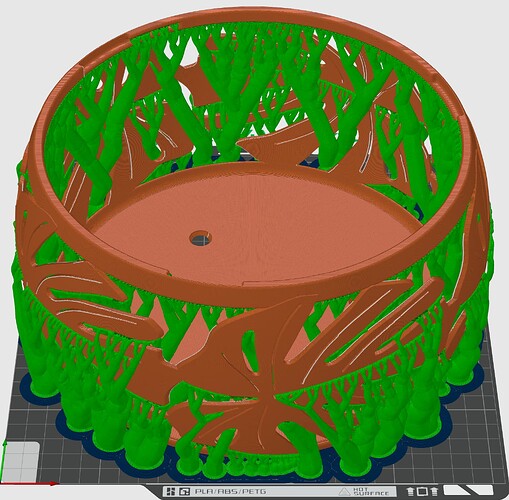

In case anybody is interested this is what the print looks like.

and this is an image of the whole device I’m making for my daughter.

By far the most complicated thing I have ever designed and printed.

1 Like

I guess the plate needs to be cleaned thoroughly