The math checks out:

Let’s say the Hot Garage is 35ºC (95ºF), and arbitrarily say it’s 50% RH. (That gives a “feels like” heat index of 107ºF, aka, misery.)

If you heat the same air to 60ºC (140ºF), its relative humidity will drop to 11% RH.

Now, I don’t know your actual starting conditions, but this seems to be in the right range. (You can play with the numbers using this relative humidity vs temperature calculator..)

It’s not necessary a bad thing. Hot air can hold more water (that’s where the “relative” part comes in), so even if that RH number is a little sketchy sounding, it may still help you assess if drying is working. But you’re definitely fighting an uphill battle.

I recently saw a relevant video to this topic, from a PhD mechanical engineer at MATE University in Budapest. He both did the math and ran the experiments:

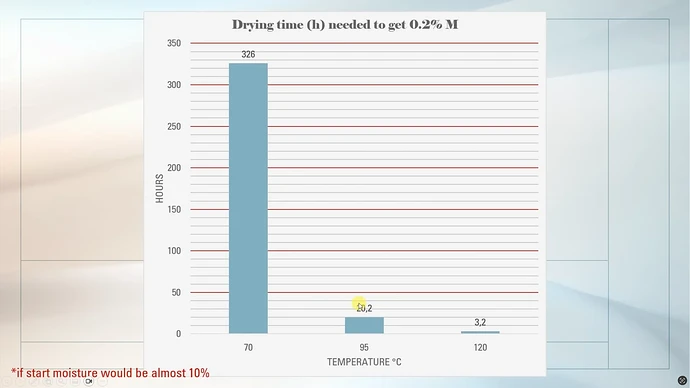

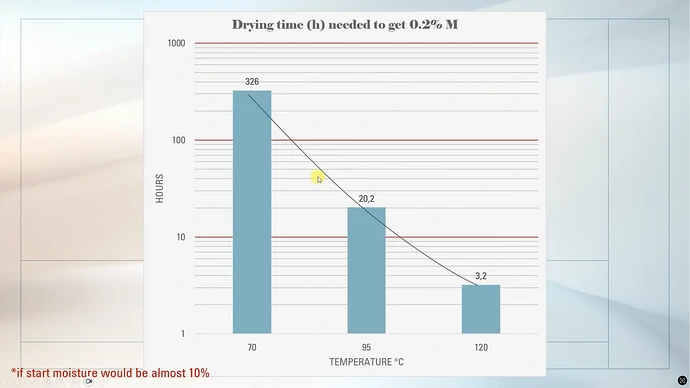

I’ll give you the spoiler: Temperature is key, not RH. Drying speed vs temperature follows a logarithmic curve. Getting a little bit hotter doesn’t remove moister a little bit faster. It removes it a lot faster:

That’s the kind of curve that makes me go holy !@#$%. Literally. Every 25º of heat you can bring to the party drops drying time by a factor of ten.

Same data, on a log scale, which makes it really easy to project drying time vs temperatures… but remember the essence here is weeks vs days vs hours!

(He also is asking manufacturers to crank up the heat as well as dealing with moisture and rotation the heat. A few years ago, driers only went to 50ºC, now they’re up to 70ºC… but hotter still would be far, far better, for the filaments that can tolerate it. Of course for PLA and PETG, 90ºC driers would be overkill. But the goal is to go as hot as you can without crossing the filament’s glass transition point.)

OK, let me come back to the AMS HT and your garage! I suspect you are hitting the absolute limits of the HT’s heater. Lower ambient humidity would definitely help, but I think you may just need to give it more time. A lot more time.

I look forward to any follow ups you can provide! The AMS HT looks like a really useful gadget, but I still don’t have a handle on whether it is meant to remove moisture from wet filament, or simply maintain RH during printing, like most other driers.