Interesting observation. It might just be the rendering of the cad model the “xray” image was created from being a bit off.

Looks like it has a quick nozzle swap system like the A1

Edit: Just saw that @simtom already said this in the other thread

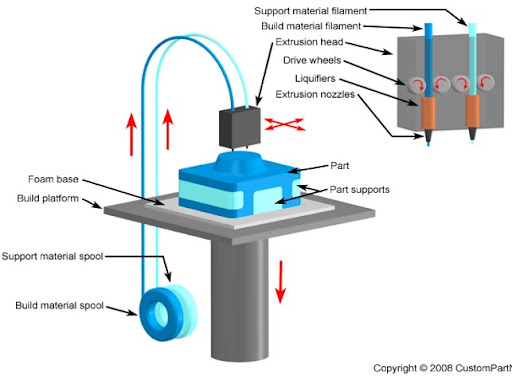

Looks to me like the big stepper drives the large(high torque) spiral cut bevel gear of the extruder. The extruder gear looks to have a large surface like a nextruder setup. The larger the gear, the more surface area touching the filament. Looks like the rocking mechanism does use a servo, bunch of normal gears and a worm drive at the end. The lift mechanism could be a pancake style servo, but cant tell because its not clear(xray visioned lol) but the housing is shiny gray like the housing of the upper servo. Im guessing the coils just arent exposed on the lower one. You can see the tiny linear rails that the nozzles ride on

For me, the only thing left to find is the cutter/s. Or they figured out how to pull out without creating a mushroom tip(hehe) or a string and didnt need them.

Also means no large purge needed.

Also, the laser mounting flanges.

Its gonna be like a damn ironman suit. Im positive it will be $1,500 lmao mwahaha or $3,999

Man… that looks very complicated, meaning reliability could take a hit if they didn’t do their homework. No less than 8 gears (likely significantly more), at least one servo/actuator (likely more), looks like its one extruder for both heads, it may have a version of the quick change nozzles, however, the part I can’t account for is the rear actuator on the lower left of the photo. I believe the top left mechanism could be the drive for the nozzle shifting mechanism, but I can’t think of what the lower left mechanism is for. I’m not sold on there being a lift and swing mechanism, I’d imagine those two functions are in one mechanism.

I love that they moved to linear rails, which makes sense since there is possibly going to be a drag knife to go with the laser and printer functions. But overall, I’m getting the feeling of the US’s F-35 procurement. Trying too hard to satisfy everyone, may lead to only making a few truly happy. Looks to be a jack of all trades and may not be terribly great at any one of them. Not to say I think it will print badly, but I’m expecting it to not be as rock solid reliable as the past options.

The more of the printer I see, the higher this price goes up. I’m guessing the toolhead alone will add about $200 to the X1’s price. Rails vs carbon rods will likely be a wash or a little cheaper (depending on the spec). I’m guessing the new door, windows, and sealing will bump up the price a little too. Add in the ventilation system improvements with the expected heated chamber, I’d guess another $250-300. The additional build area could account for an additional $150 (using the price difference between the Mini and A1 with a little premium for the flagship). The AMS 2 has to ask for a premium over the base AMS so I’d expect a base increase of $50 (even not knowing what improvements it brings). Add in the possible secondary drying system, you have to assume that will be at least $150 (but likely higher). And that’s just the basic flagship with only the print related bells and whistles. I fully expect an additional premium, maybe $300 for the development costs and the flagship premium.

Grand total, $2650 - $3200 (high side guess)

That’s a lot. Is it worth it based on what we know now? Not to me. BUT… I do expect Bambu to pull something out the hat that we didn’t see coming (not including the laser), so stay tuned for that.

Linear Rails. Suggests the possibility of servo-controlled positioning.

That would be a major improvement in the design. Sufficient to make me sell my perfectly-functioning X1C and trade up.

I’m not following you, what would the servo control? Are you referring to the positioning of the toolhead? Also, I’m not seeing any encoders on the rail. Its possible they could embed differential cutouts for a Hall sensor, but that seems like a lot (precisely machined out linear rails would be fairly expensive). There are cheaper and arguably better ways to do that.

I thing everybody agrees that this is not going to be a cheap printer. My guess is 2k.

$1899 USD for the base model with no AMS. $2499 USD for the combo.

My bet is $2k basic plus a bunch of expensive addons (i.e. AMS 2, Laser module, etc…)

$3,999 for the printer plus ams combo. $250-$500 for the laser module. Because Bambu knows so many people will only buy bambu now. My guess still. Standalone ams will be $399.-$499 depending on if it can feed both nozzles or only 1. If there is a single roll high temp(90c) ams, expect $499 for that also.

This pricing wont make any other bambu printers obsolete or make them counteract the profits by having to lower prices on other units like the x1e. Also competes with the 5 head prusa if it gets rid of purging. Would be limited to 2 opposing material types(2 nozzles) but have access to (theoretically) up to 32 colors without purge. Last thing this pricing does is “place it above the x1 series”

Materials will come presized at a premium, for the laser

Edit: Depending on heated chamber and connectivity

My guess is $1500-$1800 without AMS and another $400 for the new AMS, but it may lack a couple of features people are asking for. I expect a release of an E version later more in the $3-$4k range.

One thing that has also bothered me is I don’t see a hot end fan. There are fan ducts for filament cooling but I don’t see anything for the cold side of the hot end. Anyone see where that is sorted out from?

it’s those two channels on the sides of the nozzles

edit/ nevermind i see you’re talking about something else ![]()

Indeed, it’s going to be a mess with all these separate teaser topics ![]()

Those belts look like 9-10mm, but they don’t look like GT2. Custom, smaller pitch?

Or there’s a fan like the X and P series. Or the part cooling fan cools the hotend too?

Obviously the pancake batter cools the hotends. ![]()

there is one motor there to move the head side to side… the other motor is to extrude