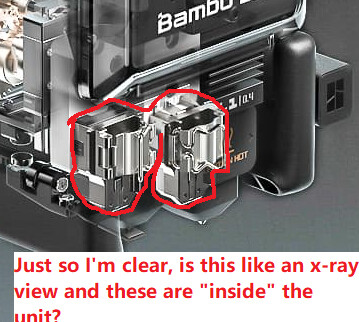

Yes! Since the first leak, I thought that’s what the upward movement was about.

The above/below image looks nozzleless so you can also see the heating element , i think thats what it is

That would be the best thing ever! If Bambu did that it would have to be the number 1 3d printer on this planet. If bambu put a laser, It would save me money because I was wanting to buy a CNC, but if Bambu does this…

Yes those are xray through the silicon socks and are A Series nozzles and the clips are the quick release for the nozzles, hope that helps. A series is upgraded tech, i dont see them going with P / X, slow swap, nozzles

I don’t think the H2D is going to have spring clips like on the a1 series, It will probably be something like the x1c.

Yes those are xray through the silicon socks and are A Series nozzles and the clips are the quick release for the nozzles, hope that helps

Ok thanks for clarifying this

one thing i must say that i already really love about the h2d… is the linear rails instead of the carbon ![]()

And just to make it visually clear as well, took off the sock on my A1 and you can see the clamps so I would assume it’s going to be very similar on the H2D.

Exactly, I believe it is not a bed slinger for sure. Linear rails are more reliable and more precise than rod’s therefore I love this new design.

So, so far the A1 appears to of got a major upgrade to an enclosed xyz and some other cool stuff or just a natural evolution ? of the A Series ?

it is not a bed slinger. kinematics are different but, as you mentioned it took some of the A1’s good pats,

i deleted the bed slinger comment from a previous post and corrected myself above

Is there a way to give an AI the blurred and unblurred image of the extruder unit so that the AI can deduce the method that it was blurred to make unblurring the other images easier??? ![]()

![]()

yeah the only downside i see is that the nozzles on the a1 dont keep the heat as good as the x1c … the way the heater is design imo is not the greatest of all… but meaby they have newer nozzle and better heaters. the issue is that petg doesnt print as good as the max flow rate is not as high and the way the heater is heating its just not pushing flow good enough. I always had clogs on 3 of my a1 minis with petg, always had to bump the temperatures all the way to 290 for petg weirdly fixed the issue but not as reliable and as good quality that the x1c did :s

They always touted the A series head as a more upgraded of the 2, as far as the nozzle and such goes so it would make sense to me they continued with it until something happened to need a complete redesign, I will say tho in the photo to me (beside the xray shadow of the sock and nozzle point) the more clear picture of the inside seems like there are no nozzles seated in the clips there for the picture as I dont see the silver shafts of the nozzle that would be clipped in place

Why do people keep saying laser cutter, CNC? These are not additive manufacturing which 3D printing is.

Even if BL wants to go into subtractive manufacturing this early in its 3D printing business, wouldn’t it make more sense to produce them in separate product lines?

Leaks have indicated that there will be a laser engraver, both a leaked photo and a supposed material list support this if you believe the leaks to be true

It will 100% be (if you want to use Orca), and Bambu Suite will be needed for the laser.

Its a long story, one that started approx 12 years ago