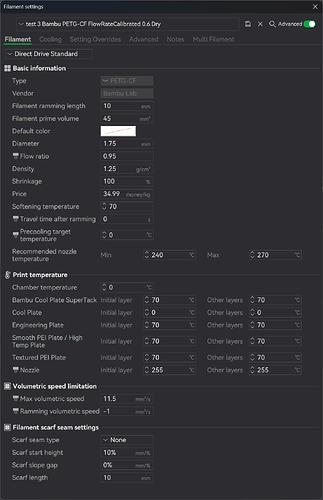

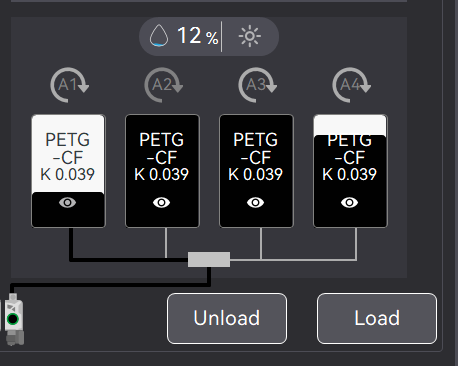

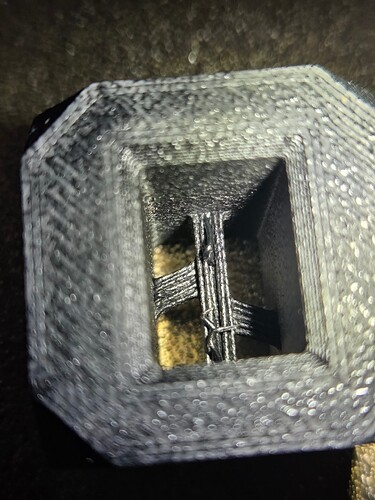

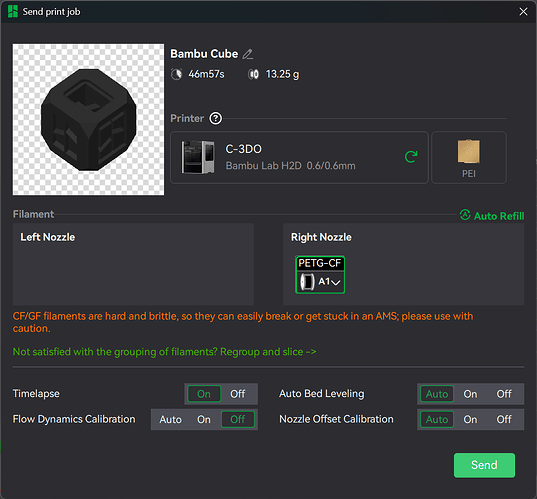

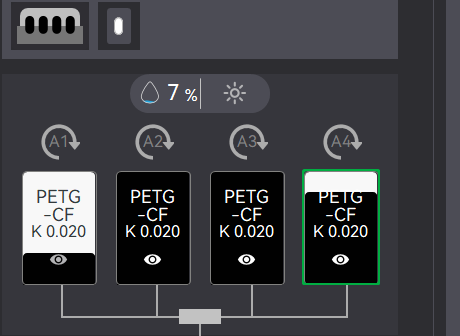

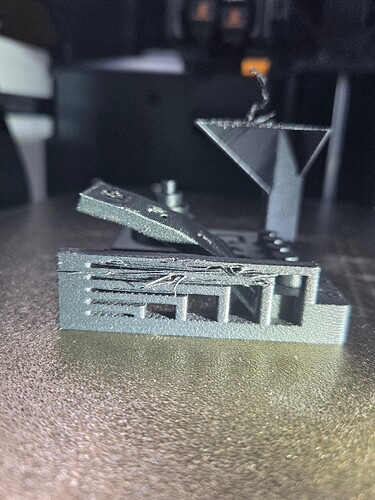

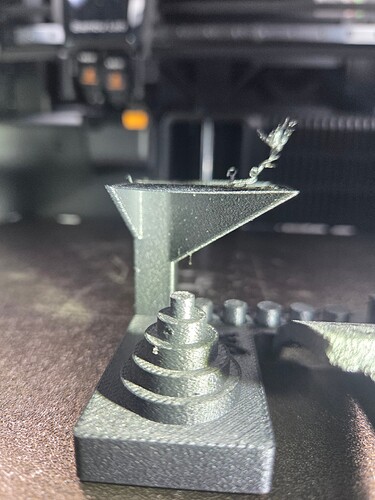

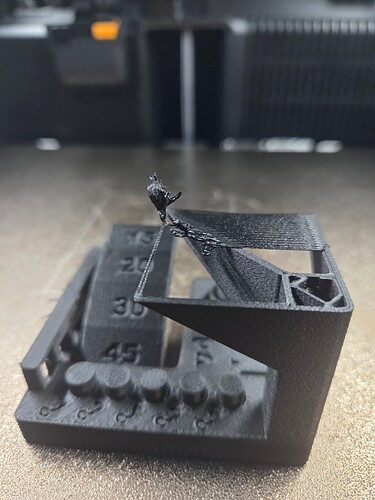

Hi, pretty new to 3D printing. I’m trying to print with the PETG-CF filament and I just can’t get it dialed in. I have read pretty much all the posts here and on Reddit but I just can’t get the Bambu test cube to come out perfectly with the 0.6mm nozzle. The 3DBenchy comes out great though, maybe the cube is a bad test? My Filament is dried for 12h at 65°C / 149°F and the RH in the AMS is at 8%. The flow rate and K-factor was calibrated twice with similar results. After 2 days of testing I lost track of my settings and started a spreadsheet. I’ll try to copy it into the post as a table. Here is also a picture of the test cube and the 3DBenchy. Any pointers would be much appreciated and helpful.

Edit: Was in a rush to post before I went to work. The filament is the Bambu PETG-CF

| Column 1 | Column 2 | Column 3 | Column 4 | E | F | G | H | I | J | K | L | M | N | O | P | Q | R | S | T | U | V | W | X | Y | Z | AA | AB | AC | AD | AE | AF | AG | AH | AI |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Preset | Test model | Filament and RH% | Nozzle Size mm | Layer Height mm | Calibrated K-Factor | Max Volumetric Speed mm³/s | Calibrated Flow Rate | Nozzle Temp °F | Min fan speed threshold % and layer time | Max fan speed threshold % and layer time | Cooling overhang threshold | Keep fan always on | Fan Speed For Overhangs % | Initial layer speed mm/s | Initial layer infill speed mm/s | Outer wall speed mm/s | Inner wall Speed mm/s | Sparse infill speed mm/s | Internal solid infill speed mm/s | Top Surface speed mm/s | Bridge speed mm/s | Gap infill mm/s | Overhang speed mm/s 10% | Overhang speed mm/s 25% | Overhang speed mm/s 50% | Overhang speed mm/s 75% | Overhang speed mm/s 100% | Support mm/s | Support interface mm/s | Sparse infill pattern | Sparse infill density % | Result notes | Print No. | Additional Notes |

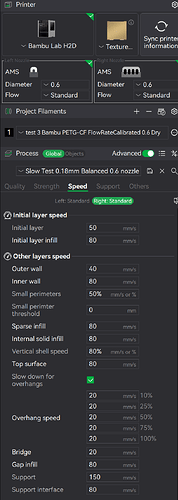

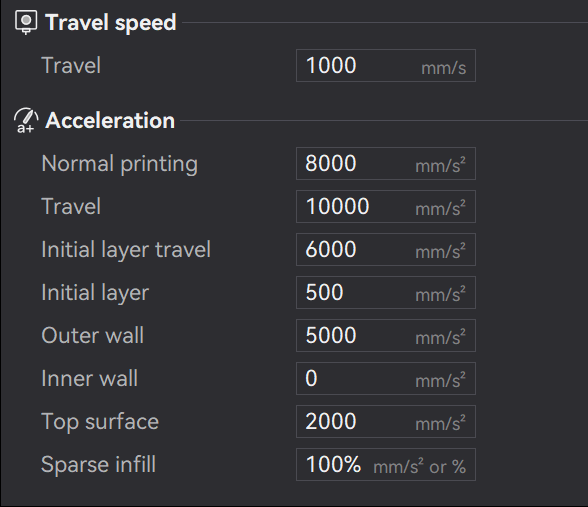

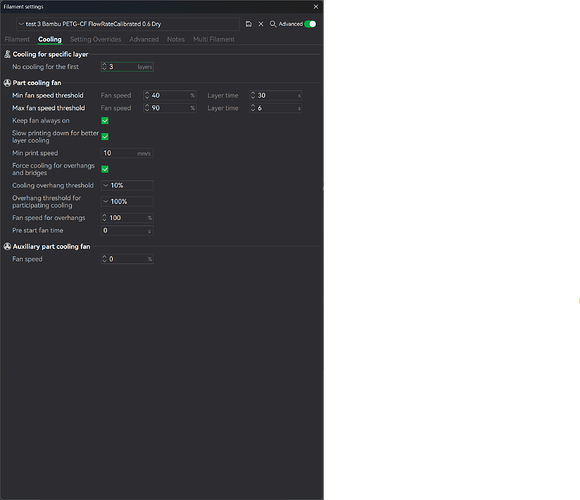

| Default 0.18mm Balanced Quality @BBL H2D 0.6 nozzle | Bambu Cube | Bambu Petg-CF 9%RH | 0.6 | 0.18 | 0.039 | 11.5 | 0.95 | 255 | 5% - 30s | 40% - 6s | 10% | Yes | 100 | 50 | 105 | 200 | 300 | 350 | 250 | 200 | 50 | 250 | 0 | 50 | 30 | 10 | 10 | 150 | 80 | Grid | 15 | Sagging on overhangs | 1 | Standard profile no changes to it besides flow calibration and K-factor |

| 0.18mm Balanced Quality @BBL H2D 0.6 nozzle | Bambu Cube | Bambu Petg-CF 9%RH | 0.6 | 0.18 | 0.039 | 11.5 | 0.95 | 245 | 5% - 30s | 40% - 6s | 10% | Yes | 100 | 50 | 105 | 200 | 300 | 350 | 250 | 200 | 50 | 250 | 0 | 50 | 30 | 10 | 10 | 150 | 80 | Grid | 15 | Some sagging on overhangs | 2 | |

| 0.18mm Balanced Quality @BBL H2D 0.6 nozzle | Bambu Cube | Bambu Petg-CF 9%RH | 0.6 | 0.18 | 0.039 | 11.5 | 0.95 | 265 | 5% - 30s | 40% - 6s | 10% | Yes | 100 | 50 | 105 | 200 | 300 | 350 | 250 | 200 | 50 | 250 | 0 | 50 | 30 | 10 | 10 | 150 | 80 | Grid | 15 | Some sagging on overhangs | 3 | |

| 0.18mm Balanced Quality @BBL H2D 0.6 nozzle | Bambu Cube | Bambu Petg-CF 9%RH | 0.6 | 0.18 | 0.039 | 11.5 | 0.95 | 255 | 40% - 30s | 90% - 6s | 10% | Yes | 100 | 50 | 105 | 200 | 300 | 350 | 250 | 200 | 50 | 250 | 0 | 50 | 30 | 10 | 10 | 150 | 80 | Grid | 15 | Minor sagging on overhangs | 4 | The best of the 9 first prints |

| 0.18mm Balanced Quality @BBL H2D 0.6 nozzle | Bambu Cube | Bambu Petg-CF 9%RH | 0.6 | 0.18 | 0.039 | 11.5 | 0.95 | 255 | 40% - 30s | 90% - 6s | 10% | Yes | 100 | 50 | 105 | 200 | 300 | 350 | 250 | 200 | 50 | 250 | 0 | 20 | 20 | 10 | 10 | 150 | 80 | Grid | 15 | Some sagging on overhangs, 4 was better. | 5 | |

| 0.18mm Balanced Quality @BBL H2D 0.6 nozzle | Bambu Cube | Bambu Petg-CF 9%RH | 0.6 | 0.18 | 0.039 | 11.5 | 0.95 | 255 | 40% - 20s | 70% - 6s | 10% | Yes | 100 | 50 | 105 | 200 | 300 | 350 | 250 | 200 | 50 | 250 | 0 | 20 | 20 | 10 | 10 | 150 | 80 | Grid | 15 | Minor sagging, similar to 4 | 6 | |

| 0.18mm Balanced Quality @BBL H2D 0.6 nozzle | Bambu Cube | Bambu Petg-CF 9%RH | 0.6 | 0.18 | 0.039 | 11.5 | 0.95 | 245 | 40% - 20s | 70% - 6s | 10% | Yes | 100 | 50 | 105 | 200 | 300 | 350 | 250 | 200 | 50 | 250 | 0 | 20 | 20 | 10 | 10 | 150 | 80 | Grid | 15 | Sagging | 7 | |

| 0.18mm Balanced Quality @BBL H2D 0.6 nozzle | Bambu Cube | Bambu Petg-CF 9%RH | 0.6 | 0.18 | 0.039 | 11.5 | 0.95 | 260 | 40% - 20s | 70% - 6s | 10% | Yes | 100 | 50 | 105 | 200 | 300 | 350 | 250 | 200 | 50 | 250 | 0 | 20 | 20 | 10 | 10 | 150 | 80 | Grid | 15 | Sag on overhangs | 8 | |

| 0.18mm Balanced Quality @BBL H2D 0.6 nozzle | Bambu Cube | Bambu Petg-CF 9%RH | 0.6 | 0.18 | 0.039 | 11.5 | 0.95 | 255 | 40% - 30s | 90% - 6s | 10% | Yes | 100 | 50 | 105 | 200 | 300 | 350 | 250 | 200 | 50 | 250 | 0 | 20 | 20 | 10 | 10 | 150 | 80 | Grid | 15 | Sag on overhangs | 9 | |

| 0.18mm Balanced Quality @BBL H2D 0.6 nozzle | Bambu Cube + 3DBenchy | Bambu Petg-CF 9%RH | 0.6 | 0.18 | 0.039 | 11.5 | 0.95 | 255 | 40% - 30s | 90% - 6s | 10% | Yes | 100 | 50 | 105 | 200 | 300 | 350 | 250 | 200 | 50 | 250 | 0 | 50 | 30 | 10 | 10 | 150 | 80 | Grid | 15 | Bambu cube got some sag , 3Dbenchy close to perfect | 10 | Print 4 settings again to compare against the previous no.4 |

| Default 0.24mm Balanced Strength @BBL H2D 0.6 nozzle | Bambu Cube + 3DBenchy | Bambu Petg-CF 9%RH | 0.6 | 0.24 | 0.039 | 11.5 | 0.95 | 255 | 40% - 30s | 90% - 6s | 25% | Yes | 100 | 50 | 105 | 200 | 300 | 350 | 250 | 200 | 50 | 250 | 0 | 50 | 30 | 10 | 10 | 150 | 80 | Grid | 15 | The Bambu cube was slightly better and the 3Dbenchy was good. | 11 | |

| 0.18mm Balanced Quality @BBL H2D 0.6 nozzle | Bambu Cube + 3DBenchy | Bambu Petg-CF 9%RH | 0.6 | 0.18 | 0.039 | 11.5 | 0.95 | 255 | 40% - 20s | 90% - 6s | 25% | Yes | 90 | 50 | 105 | 150 | 200 | 200 | 200 | 150 | 50 | 150 | 0 | 50 | 30 | 10 | 10 | 100 | 50 | Triangles | 20 | The Bambu cube was saggy but the 3Dbenchy was good. | 12 | slowed down speeds |

| 0.18mm Balanced Quality @BBL H2D 0.6 nozzle | Bambu Cube + 3DBenchy | Bambu Petg-CF 9%RH | 0.6 | 0.18 | 0.039 | 11.5 | 0.95 | 255 | 40% - 30s | 90% - 6s | 10% | Yes | 100 | 50 | 105 | 200 | 300 | 350 | 250 | 200 | 30 | 250 | 0 | 50 | 30 | 10 | 10 | 150 | 80 | Grid | 15 | cube little saggy but the 3Dbenchy is fine | 13 | Same as print 4 but lower bridge speed |

| 0.18mm Balanced Quality @BBL H2D 0.6 nozzle | Bambu Cube | Bambu Petg-CF 9%RH | 0.6 | 0.18 | 0.039 | 11.5 | 0.95 | 255 | 40% - 30s | 90% - 6s | 10% | Yes | 100 | 50 | 105 | 200 | 300 | 350 | 250 | 200 | 20 | 250 | 0 | 50 | 30 | 10 | 10 | 150 | 80 | Grid | 15 | Pretty good. Slightly saggy | 14 | |

| 0.18mm Balanced Quality @BBL H2D 0.6 nozzle | Bambu Cube | Bambu Petg-CF 9%RH | 0.6 | 0.20 | 0.039 | 11.5 | 0.95 | 255 | 40% - 30s | 90% - 6s | 10% | Yes | 100 | 50 | 105 | 200 | 300 | 350 | 250 | 200 | 20 | 250 | 0 | 50 | 30 | 10 | 10 | 150 | 80 | Grid | 15 | Pretty good. Slightly saggy | 15 | |

| 0.18mm Balanced Quality @BBL H2D 0.6 nozzle | Bambu Cube | Bambu Petg-CF 9%RH | 0.6 | 0.18 | 0.039 | 11.5 | 0.95 | 255 | 40% - 30s | 90% - 6s | 10% | Yes | 100 | 50 | 105 | 200 | 300 | 350 | 250 | 200 | 20 | 250 | 0 | 20 | 20 | 10 | 10 | 150 | 80 | Grid | 15 | Slightly more saggy than 15 | 16 | |