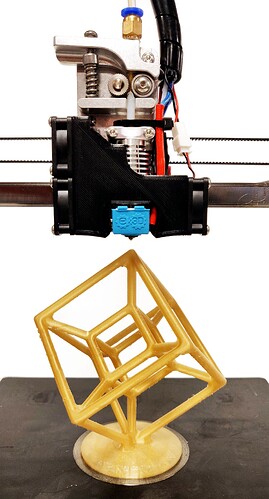

here is a picture of my test print. idk what settings to start with changing… I thought maybe the first print was a fluke so I printed it again and same results. these test prints are all over to DL but no direction on how to fix a problem? help please.

I would start with “minimum layer time” and make sure that your part cooling fan is working.

sorry. but what is minimum layer time? I don’t see that in bambu. fan. is working

I see it was in the filaments settings. thanks for your input

Keep in mind that these lattice cubes are a stresstest for your printer AND filament. Not every printer can print these with every filament. The filament needs to be very stiff, surrounding temps have to be low and the cooling has to be extreme.

I designed this one years ago and I had to jump through quite a couple hoops, settings, filaments and cooling solutions before I could print it at all:

Granted, this hypercube is even more challenging with more steep overhangs but it is not only slicer settings to make these stress tests come out. If I see your image the filament is too flexible and the nozzle keeps pushing it away every time it tries to print on it. This can be either filament not flexible enough, having a too low glass transition temperature or the part cooling not strong enough.

So my question is, what type of filament are you using and what is your room temperature (or in case of an enclosed printer, the inside temperature, although you’ll have a hard time printing this with an enclosed printer I think)

bambu labs matte. room temp is steady at 68f

I would think this would be pretty hard to print with any matte PLA filament. Matte is just weaker with worse layer adhesion. Would be curious to see if regular pla basic has the same failure.

ill have to try it. I wasn’t aware of matte being an issue. its just what I had in machine.

Sunlu PLA. 50 % speed. fan at 90%. I was changing it on screen to 100% and it kept going back to 90.

Did it print with supports?