So over the last 24 hours I have tried numerous settings and options in Bambu Studio including nozzle temp but to no avail. It turns out that any real changes need to be made in the Machine G code printer settings.

Apologies if you know how to access the G code but just in case others read this, it can be done by clicking the edit preset button > Machine gcode.

I’m still an utter newbie at 3d printing and have only learned from what I have researched, so anyone wishing to modify the gcode does so at their own risk! I suggest you save a separate test preset and keep the original settings in case you need to revert back to them

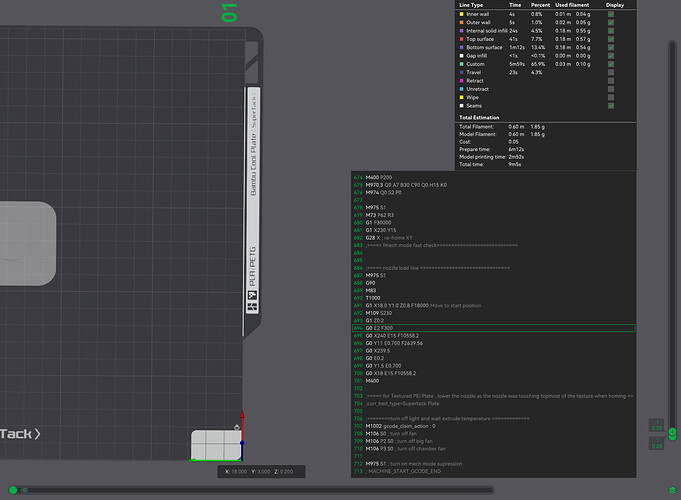

@Alex_vG If you are going to modify anything, I think the following settings are the ones you probably want to fiddle around with:

;===== wipe nozzle ===============================

M109 S{nozzle_temperature_initial_layer[initial_extruder]-20}

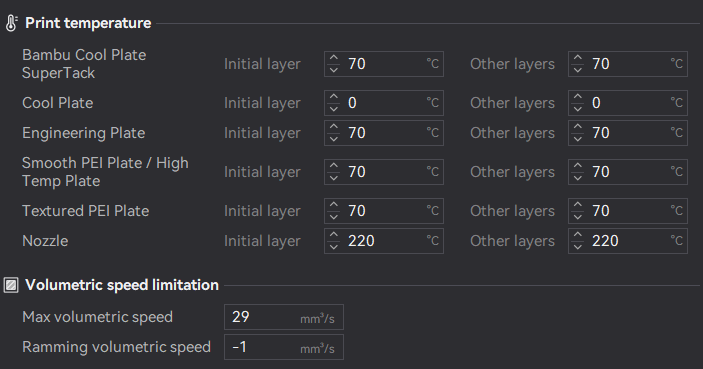

This is where the temp drops after the initial purge of the poop. To alter the temperature amend the “-20” to whatever you consider. So if the nozzle temp is set at 230, at this stage it will be heating up/down to 210.

M104 S140 ; set temp down to heatbed acceptable

This is the temperature that occurs before the nozzle head cleaning which is the temp you mentioned in your own post. To amend the temp just change the 140 up or down.

M109 S140 ; wait nozzle temp down to heatbed acceptable

This temp follows the nozzle head cleaning. Change as above.

;===== nozzle load line ===============================

M975 S1

G90

M83

T1000

G1 X18.0 Y1.0 Z0.8 F18000;Move to start position

M109 S{nozzle_temperature_initial_layer[initial_extruder]}

G1 Z0.2

G0 E2 F300

G0 X240 E15 F{outer_wall_volumetric_speed/(0.3*0.5) * 60}

G0 Y11 E0.700 F{outer_wall_volumetric_speed/(0.3*0.5)/ 4 * 60}

G0 X239.5

G0 E0.2

G0 Y1.5 E0.700

G0 X18 E15 F{outer_wall_volumetric_speed/(0.3*0.5) * 60}

M400

This section of the code relates to the two purge lines before the printing begins.

My overall findings so far is that the I have largely been able to reduce any blobs or stringy filament stuck to the nozzle although not always, but having much larger success than before and I am not sure if there are the perfect settings but I will keep trying although I might have to settle for just ok.

If it helps, here are some of the things I have done so far:

-

In the Nozzle Wipe section, the “M109 S140 ; wait nozzle temp down to heatbed acceptable” reduced to 100 degrees I feel is too low. Somewhere around 120 degrees seems appropriate to reduce any excess oozing.

-

To help minimise excess oozing, you should also consider retracting the filament so that as the nozzle starts to heat up and get into position for the purge lines there is minimal oozing. To do this, before (or after) the line mentioned in #1 insert:

G1 E-X F300

Where “E” refers to the extruder, “X” refers to the mm you wish to retract and “F300” being the speed of retraction in milliseconds. I can’t remember what setting I had as Ive messed around too much but somehwere between 5mm-10mm reduces oozing by the time the nozzle hits the purge lines. You can also retract in decimal such as 1.5, 0.5 etc. Be careful not to retract too far back it ends up out of the nozzle itself.

- In the nozzle load line section I have discovered that “G0 E2 F300” is the culprit for creating the blob at the start of the purge lines. You could set that instruction to ignore by using the semi-colon “;” and it should start extruding the purge line as usual. Be careful because if you set this to ignore, the printer may run at the last known speed and have unexpected results so to counter that you coud add the F300 to the next line.

A little tip is that if you slice the model you are using in Bambu Studio and set both green bars to 0 (sorry I don’t know what these are called , you can use the bottom bar to cycle through each line of code of the purge lines that is being applied. This is helpful if you want to add more purge lines or space them out (see my next point).

- To help reduction of blobs or filament sticking to the nozzle after the purge lines, I have set the initial extrude blob to ignore (G0 E3 F300), widened the purge lines, added 1 purge line more and set the speed to 300ms for the first purge line using the code below. This along with/without retraction settings has helped me with good testing success as the slow speed eventually cuts off any sticking filament prior to printing. You may want to increase or decrease the speeds for one or more lines depending on your successes. The bold section is the modified part for and additional purge line.

;===== nozzle load line ===============================

M975 S1

G90

M83

T1000

G1 X18.0 Y1.0 Z0.8 F18000;Move to start position

M109 S{nozzle_temperature_initial_layer[initial_extruder]}

G1 Z0.2

;G0 E3 F300

G0 X240 E15 F{outer_wall_volumetric_speed/(0.30.5) * 60} F300

G0 Y11 E0.700 F{outer_wall_volumetric_speed/(0.30.5)/ 4 * 60}

G0 X237

G0 E0.2

G0 Y5 E1

G0 X18 E15 F{outer_wall_volumetric_speed/(0.3*0.5) * 60}

G0 Y11 E1

G0 X230 E15 F{outer_wall_volumetric_speed/(0.3*0.5) * 60}

M400

- I accidently discovered that I could ignore the code for the poop purge altogether. As I only use one color for priting at the moment, this means I am able to skip this step entirely and has worked without issue (so far). If you want to reduce the amount of poop this can be done by modifying the highlighted code and reducing the number - remember the E number refers to how much in mm the nozzle will extrude. To purge no poop, just add a semi colon to each line so the instruction is ignored.

M109 S250 ;set nozzle to common flush temp

M106 P1 S0

G92 E0

G1 E50 F200

M400

M104 S[nozzle_temperature_initial_layer]

G92 E0

G1 E50 F200

M400

M106 P1 S255

G92 E0

G1 E5 F300

M109 S{nozzle_temperature_initial_layer[initial_extruder]-20} ; drop nozzle temp, make filament shink a bit

G92 E0

G1 E-0.5 F300

- When I have been testing the sticky filament of the purge lines, I have skipped all the prvious steps by deleted the code and only keep the Nozzle load line code in the machine g code start box. It means that when I print the model, it goes straight to the purge line process - may or may not help.