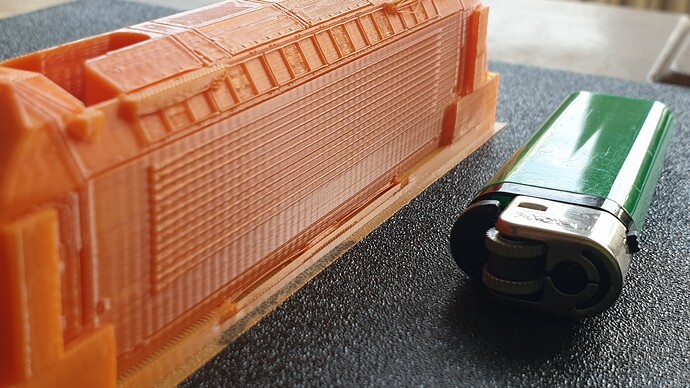

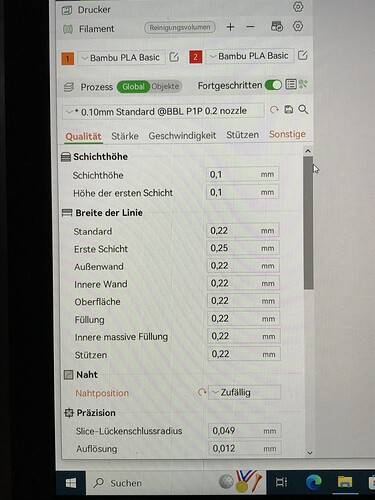

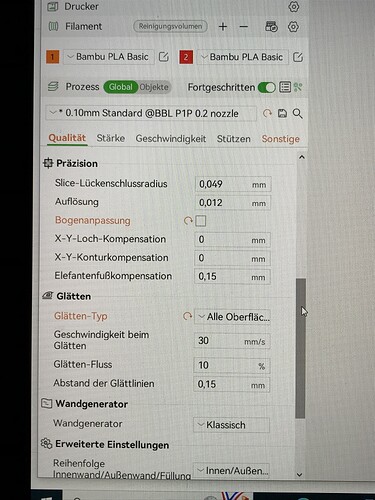

hi guys, i print this modell with P1P, 0.2Noz. Pei, with original values.

The direction of the model is parallel to the carbon rod.

In the German Bambu Forum it is said that this problem comes from the toothed belt and cannot be remedied. As far as I could find out, this does not apply to all P1P. The printer has been here for 3 weeks and I am not willing to accept the problem if it only occurs with some P1P.

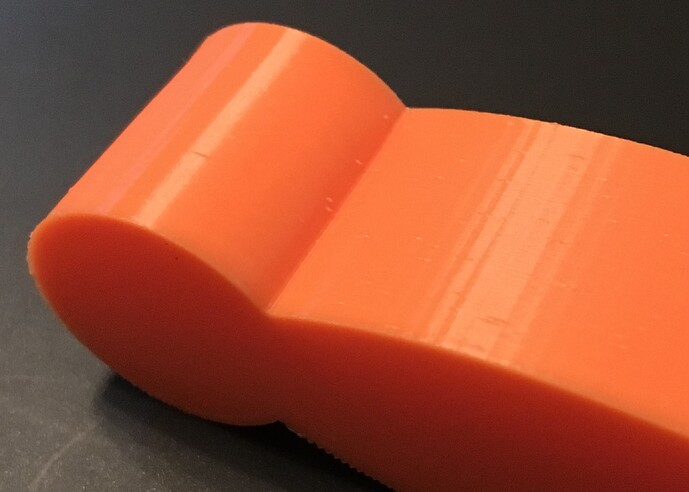

And the longe grooves are possible to feel.

On my P1P these artifacts are also present, but way less, i dont understand this either, cause the Vibrationcalibration should eliminate these… i already believe i should have saved the money and build a voron or something…

Hi, but this are not artefacts, I can feel it with my fingernails, an this are real small waves/ grooves. Some user in the german FB forum says the reason is the timebelt.

One interesting thing I’ve seen (and read about) is that the waviness is less pronounced at higher speeds. I have noticed this multiple times while running max flowrate tests. I wish there was a way to correct it.

This is a well known issue. Sometimes indeed described as the timebelt issue. The root-cause however is not the timebelt but something different. I spend a lot of hours of testing and researching and am now 100% sure where the root-cause is and how it could be solved by Bambulab.

I am communicating with Bambulab support, but unfortunately I’m dealing with Rick. Rick is very capable on communicative and manipulative area for pushing problems away from his person, but not the right person if Bambulab wants to improve with a real solution. Unfortunately Bambulab support (in the person of support-employee Rick) only wants to camouflage by providing different settings or other advise not being a true understanding and solution to the root cause.

At this point I’m curious if Bambulab as a company wants to be solving the issue or avoiding and waving it away.

Could you tell us more about your findings?

It originates from the both the XY- motors, is transferred through the belt to the printhead. The pattern(s) are based on a fixed frequency (per amount of time, not per degree of rotation) and sometimes is less visible, e.g.

- in case of speed above 180mms

- When printing along the Y-axis, due accidental being cancelled out. (both motors cancelling-out each other’s vibration, think of noise cancelling technology from e.g. headphones).

As its been few months since I communicated this with Bambulab, but still not solved, I have uploaded a test file with description on printables, /model/519637

Maybe it is related to the pulleys, where the belt teeth face the inner side of those pulleys. I mean that motion system has pulleys that face the back side of the belt and also some that touch the front face.

When I saw that these pulleys don’t have any teeth on them I was wondering if that could cause issues.

Just a theory. It might not be an (or the) issue at all.

So I think I give up. Today a guy trigger me to print this objekt to compare his P1P print about the steps on the surface.

So I have still the same problem. What should I do to get a better result.

I feel so helpless

There are many things you can try. This is RINGING not VFA. So its the belts creating this pattern. VFA is way smaller and finer. Look on printables for a gantry squaring tool. Loose the belts. Push you gantry against the back or the front. See if one side is racking. If yes try carefully to align both sides through force. After that use the squaring tool and retension your belts. Do a calibration and go for 2000-3500 accel if you want to avoid this pattern.