I do like the printer, but it has a few bumps along the way that need to be addressed.

My List of H2D Bugs and Issues:

When performing dual nozzle printing with high-temperature filament and support interface layers, the first layer applied on the last interface layer often suffers from excessive cooling due to the fan turning on at higher speed for overhangs. This results in a weakened layer. To fix this issue, I can reduce the fan speed for overhangs to lower setting, but this adjustment sacrifices the overhang cooling speed for other layers that require a higher fan setting.

80% fan speed for overhangs:

30% fan speed for overhangs:

Solution we need more fan control options added to Bambu Studio with dual nozzle printing.

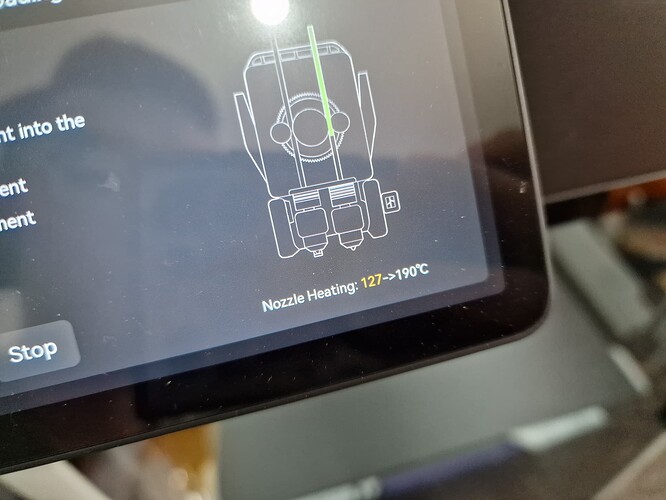

Nozzle 250c Bug:

I’ve occasionally noticed though not consistently that when switching nozzles, the nozzle sometimes remains at 250°C after the purge. It doesn’t change to the higher or lower temperature specified in the filament settings.

This bug still is in current in 08 firmware just had PLA do it and was printing at 250c

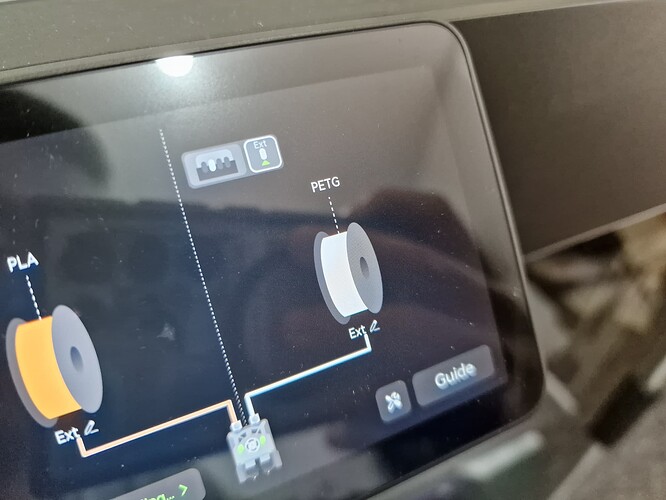

Right Nozzles Pruges to much:

The 08 firmware shows improvement, but the studio slicer G-code still needs refinement or settings to fine tune the purge value.

Studio V 2.1.0.59 has had new purge G-code will need to test out.

Misaligned rear Z rod prevents the print bed from rising.

I haven’t encountered this issue myself, but it needs to be resolved as soon as possible. I’m sharing this here to help others find the fix.

Chamber Temp Logic:

If you have a filament that requires a chamber temperature of 50°C but a bed temperature of 110°C, and when the chamber reaches 55°C, it triggers a warning to open the door to cool it down, the workaround is to set the chamber to 55°C. However, this results in the heater turning on at times when it’s not actually necessary.

Solution: The chamber temperature is set to a sample of 50°C, with an adjustable maximum temperature limit, such as 60°C. If the temperature exceeds this limit, the printer will issue a hot chamber warning message.

High Temperature Support Filament Added

Solution: Yes, you can work around the issue by using a high temperature filament like ASA, but this isn’t a beginner friendly way.

Sample

HT-BW (High-Temperature Breakaway)

Z Hop:

Add an option in Bambu Studio to enable Z-hop exclusively on the top surface, bottom surface, or both.

Bambu Links

If you encounter any other issues, feel free to add them to this post. Your input could help Bambu Lab identify and resolve problems more quickly, as they do have a link to this post @SupportAssistant

Updated: 6/03/2025