Ok so since people have told me the machine is fine I guess it’s fine right?

But no, several different models of identical geometry have repeatedly failed exactly between support interface and supported layer.

Tried so far 0.2 and 0.16 layer. 0.12 to 0.2 topZ . 90 to 105 bed temperature. I don’t have adhesion issues at all.

Single and dual color. Recalibrate. Nothing has changed. I have NOT used support material, all material is black abs or white and black abs dual. Same brand, 100% dry, same exact rolls have printed two more of these models on my other machine (p1p, neptune3+4, Voron trident 300) and not once but 100s of times. The worst case of failure in the other machines would only be evident in the form of bad ironing and that would be 1 out of 200 pieces.

Even more worryingly the AI failed to detect spaghetti and/airprint. No warning no notification, as if the print went as expected.

Next thing I will try is printing with the

Apparently pics didn’t upload. Thanks apple. Gonna fix it in couple minutes.

The pics have to be below a certain size I think 5mb. I usually need to convert my apple photos to Jpeg in order to post them because png is often too big.

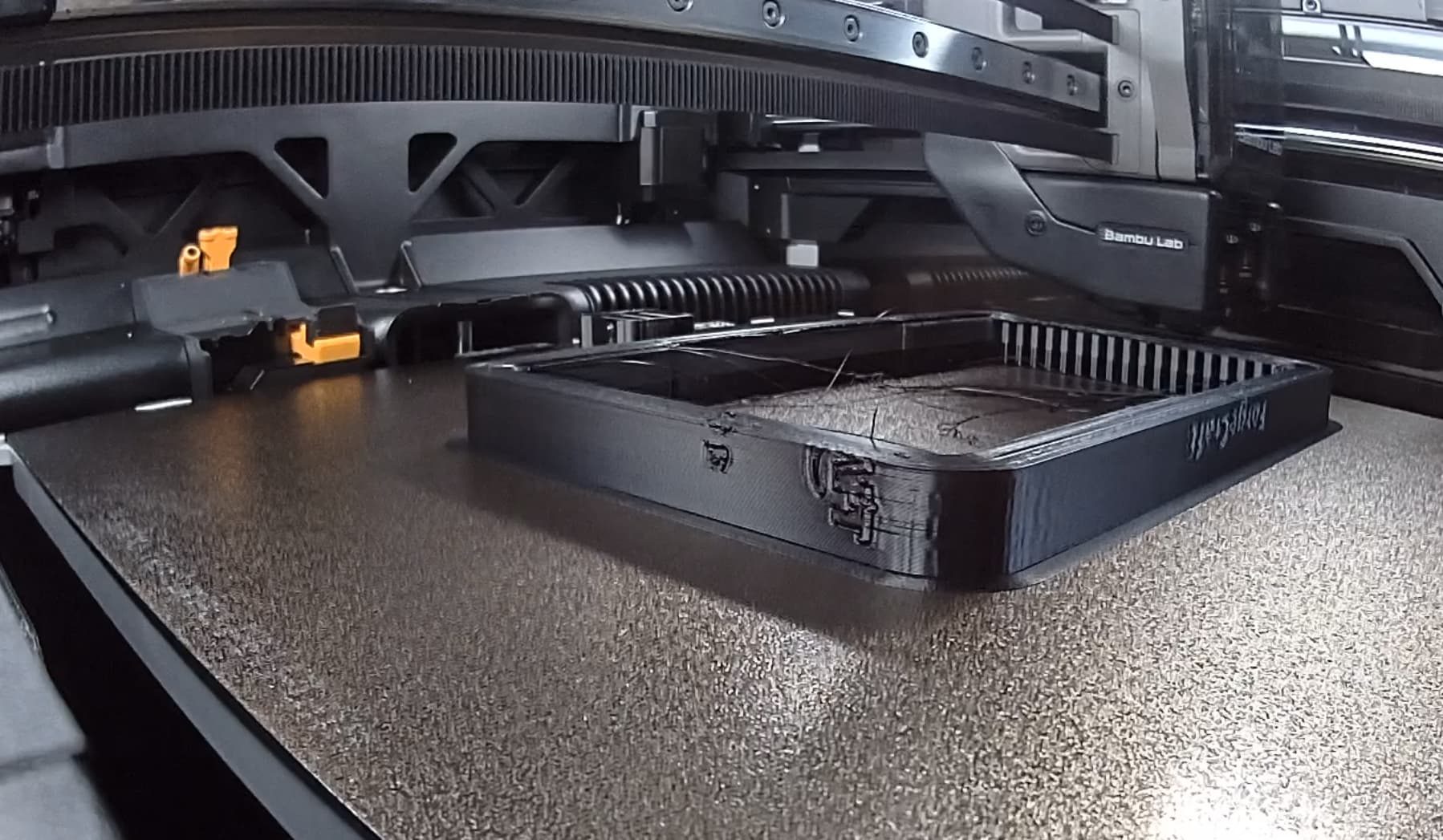

so while i was trying to reupload the last print finished, and the issue became a bit more apparent. Apparently the supports shagg…

Too heavy? Too fast? Too hot? I would guess its the fan actually since I run these the same speed I run them on my P1p and this has never happened. Gonna try to lower speed on supports and see if that changes anything

Change the support type to tree or change the direction of your support base pattern. a long single wall of support does become more fragile and easy to bow. This is the easy way but yeah maybe you want to adjust your fan as well. But I wouldn’t bother too much with the fan settings as it’s a deeeep hole.

Tree supports are out of the question, and this is not a solution that you are proposing. This is exact way works 99.5% of the times I print , with the exact same settings on 4 other machines. This is beyond fine tuning, its just turning so it works, and its unacceptable for a machine this premium. Again you are missing the point. And where is the AI detecting in all these? These photos are not one print, and in none of them AI detected anything, besides clear printing on air. YES it was activated and YES I tried from strict to slack… but not even a warning or notification.

Again its UNACCEPTABLE that machines 1/10 the price of this one are printing this exact job with no issues AT ALL , and the most anticipated printer of the year needs TUNING… I dont know why you even suggest it seriously. Its struggling on a feature that is available and a staple for over a decade, and its like saying yeaaah you bought the most advanced printer but it cant print half the normal things… that does not make sense and its not normal. NOT when its advertised as a ready to go, all automated premium machine.

It no longer seems to be only file size. I tried uploading a 400k picture, and it failed, because the pixel resolution was 3000x4000. I cropped it to a smaller size using GIMP but kept the final file size, and then it posted.

for me it was the “Live” photos, downloaded the jpeg and its good to go.

It may be a longshot, but have a look at the print preview and see whether the failures coincide with a travel move. Sometimes travel moves are so fast, and at such an angle, that they pull the freshly laid printed extrusion away from where it was laid before it has enough chance to cool into the position where it was laid. Other than fiddling with the fan speed, I’m not sure what a good solution is. It would be nice if we could change the speed selectively on different parts of the print to accommodate these kinds of failures. For instance, imagine you could “paint” a speed onto different parts of the pre-view print.

actually the issue is clearer in the last photos i posted. The whole support structure seems to be melting down. Maybe Ill set the chamber temp at 55 this time and try again

Why are they out of the question? FWIW, I find organic trees to be the easiest to detach without leaving visible marks. You can also control the amount of branching so that you can whittle it down to the minimum support needed. If need be, you can paint tree support onto these areas even if they don’t technically require support, but just to pin these strings into place when they’re printed. Maybe there are better or more proper ways to get the desired result, but it seems to work.

I’ve run into similar problems printing some gridfinity cases, and that seemed to work for me.

No matter, trees will always be slower/more waste. Plus due to the model that extra time results in horible Z lines in the slow vs fast regions, and its like 20% slow, BOOM 80% all throttle no brakes. Tree supports add give or take 2-3 hours.

And these are not models I print once and forget. I print tens every day.

I mean trees will 100% (and proven on the other machines too) work. But its not optimal to the least for my workflow. And given that those exact same supports work on the other machines, I find it… a shamefull display seeing them fail on this machine.

In this case it adds 1.5 hours to the model im planning to print.

Fair enough. Thanks for clarifying.

If you do manage to figure it out, I hope you report back with the solution. Then we can all be smarter and better off for it. ![]()

P.S. please send me a DM if you ever do, as the forum software seems very much broken when it comes to notifications about thread updates. I really am very interested if there’s a better solution than trees.

Will certainly do, this thread is meant both as a complain and record of how I try to cirqumvent it !

Thing is for now i MIGHT have to rely on tree for H2D. Production is already bottlenecked since I spent the day reading around for this…

Update:

Bambu Studio seems to ignore the 3 Top interface layers set, and generates 4

Bambu Studio

Orca

Yes for some reason Bambu Studio adds another layer it calls Support transition

Update,

Orca has Default as Rectilinear,but it appears at an angle of about 45 degrees

Orca

Bambu

Moreover Bambu seems to have Rectilinear and Rectilinear Interlaced Reversed (or the other way around)

But what is really different is that support transition extra layer