Mr sorry but you are now ignored. You have waived off everything as either filament or slicer issue. I am not interested in hearing from you anymore. This is NOT slicer issue. Same settings, same model, same process, same roll of filament, same type of bed, same glue, same user. The only difference here (and in other commenters) is the H2D and you blindly defending a 2.5k machine that cant compete with a 500 price tag prev gen model. Also , I am not going to post the 3mf, my models are not shared.

And alarmingly you ignored the part where the ai didn’t even bother with the spaghetti…

Oh yeah as if I am defending it.

With so many people printing all kinds of things without issues, you’re simply blaming it on the machine, for such a basic feature, that nobody else is having an issue with.

Of course it’s the machines fault!

People like you are no difference than those who cry for first layer issue with a dirty plate on reddit, you don’t want help and you don’t want to know what’s the cause of the issue, you just wanna argue and rant.

How did your toolhead with x-axis replacement turn out? Did it improve anything on Z-Banding? Asking cause I am about to receive the same part following a broken part on the rear PCB and the stuck screw of my left heating assembly which is also broken… (wires stripped)

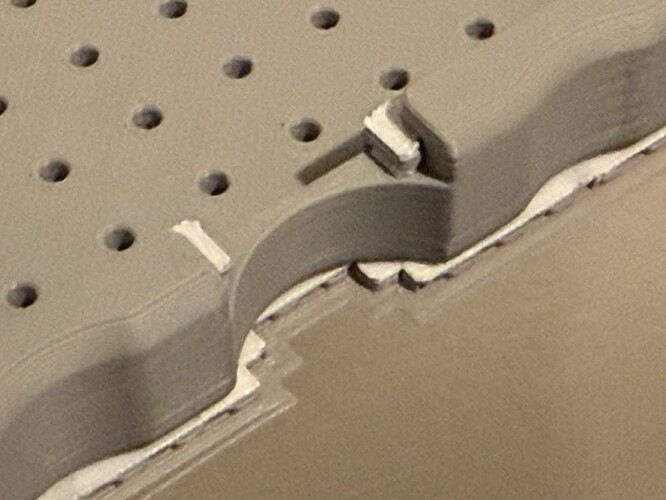

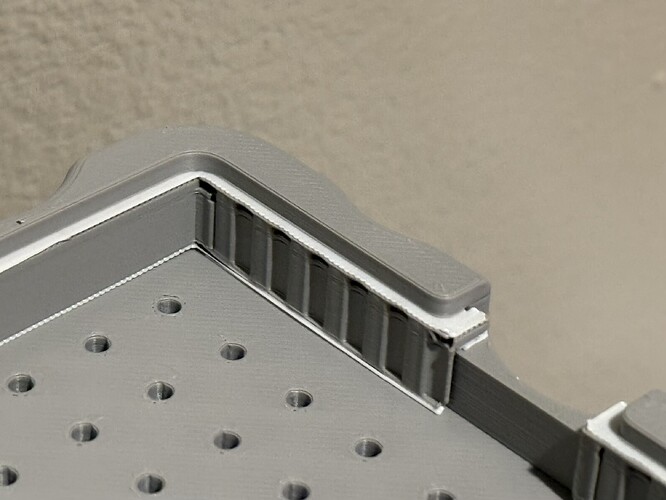

Is this what you would call “Z-wobble”? The moment it starts printing that overhang it seemingly pushes against the model. Already did the full bed calibration. This particular model has 5 walls so it’s already pretty sturdy but it still seems to make it wobble.

what infill was that?

25252525

Was using 10% Cross Hatch. Now trying the same but with Adaptive Cubic + also disabled “Reduce infill retraction” (I could hear it scratch the infill).

EDIT: same problem using Adaptive Cubic, I can hear it scrape against the infill and I get those pushed out layer lines. I guess the last option before modifying the geometry is to slow down the speed once it gets to the upper part?

try share 3mf file with your saved settings.

The nozzle should be pushing downwards and press on the part, that’s for sure (it’s pressing the melted filament to form the line width you set, e.g., 0.42mm for walls, 0.45mm for sparse infills… Etc)

Sure, here’s the file. Note that the increased wall loops and top/bottom shells are to reduce transparency of the model. It’s supposed to be a table for Barbie figures (a request by my mom ![]() )

)

Another case of supports failing at the interface . 0.16 layer, 0.12 top z, again AI failed to detect air printing. Tell me again how that’s ok. This is another model I have printed countless times with the exact same filament on my other 4 machines, including Neptune’s that are not even supposed to run abs, yet the supports won’t fail like that !

Τhis time its with single color, same material for supports, independent layer height turned ON, will try with off on the next print .

It helped a little, but I ended up finding a broken bolt on the left nozzle rail behind the heater. I think it helped more with VFA’s using the left nozzle than anything. Slicer settings and firmware/BS updates helped more. I feel we need more tuning to deal with the cooling and mechanics of this printer than anything. All my z-banding wasn’t traditional banding but only on geometry changes or layer time changes. Arachne, 2 walls instead of 3 (when possible), precise wall, help alot depending on the model. Also unchecking slow down for overhangs helps a lot on models that will allow it.

That changeout took me about 2 hours taking my time. The only thing that was a PIA was the small screws on the x-axis it self. I used a magnet to help get the ones out in recesses once they were loose and put 1 layer of scotch tape around the Allen key to create enough friction for the screws to stay on the Allen key when I slid them into the recess.

FYI, Do NOT remove the toolhead from the x-axis. There are loose ball bearings inside that are only held in place by grease and the x-axis itself. This is why they ask you to hold the new and old toolhead in place with zip ties or tape while installing or removing.

The other issue I had was my left nozzle stopped heating up to the proper temperature shortly after doing a calibration when we had the bug that would slam the nozzle (and wires below it) into the cleaning pad. So they sent this tool head out to me for multiple reasons.

Tried the same on my A1 (+ variable layer height) but sadly same result. The weird thing is that I printed this model fine on my A1 some weeks ago. The only difference now being that I’m using PLA Matte instead of Basic.

I’m not dismissing anyone’s problems. The only data point that I can add is that I’ve used the new support for PLA and printed some pretty finely detailed stuff and it worked out well. After I removed the material in between and all the support material, the parts functioned perfectly.

Update, my Z-banding in ABS has almost completely gone now. I suspect the H2D just requires a longer period for is mechanical components to break-in ?Note: Did not change anything that would result in more/less banding, im fighting with supports for the last 3-4 days, but banding was evident even below the layers that the supports were needed. Now apart from weird geometry changes, its almost perfect , will see the following days if its gone completely !

got some pretty bad Z banding on this print, first time printing something this tall. Using Generic PLA Silk profile with no changes made. Does anyone know why this is happening or how to fix it?

Thanks

need 3mf to analyze.

From the looks of it firstly it’s not exported in highest quality (can tell by the rainbow like pattern, it’s not vfa)

then, this regular horizontal pattern hints a regularly changing sparse infill pattern:

The reason of these two bigger lines is unknown. I guess there is a top surface in the center of the model? i must have the 3mf to make sure.

252525

Yes, I have good results with Support for PLA as well. Good stable support is always gonna be better for everything.

might get a new printer via the advance replacement.

Will see if this charge have the problem too ![]()

Why do you want a replcament

Because of the z banding Problem ? Did you Read what this Thread is about :D?