Has anyone found a good setting? I have been slowly increasing it. Default was 10% and I’m up to 15% now. Still under extruding. Probably jumping to 20% next. All the other settings are default for 0.4mm nozzle and 0.2mm layer height.

Never been able to match the quality of my P1S. I found 22% with PLA Matte to be almost there.

The H2D hot end impacts the filament more significantly than other printers.

You can also try adjusting the nozzle temperature for the top layer of your part, if possible, by using layer specific temperature G-code.

To change the temperature at a specific layer

Are you using higher iron speeds and require increased flow?

Interesting. When ironing with the default 10%, I got the error “extruder motor overload” (or something like that). I had to reduce it to 2-5% to make it work.

I have not had that warning yet. Mostly print in ABS with default settings (temp/speed), and mostly use Polymaker ABS.

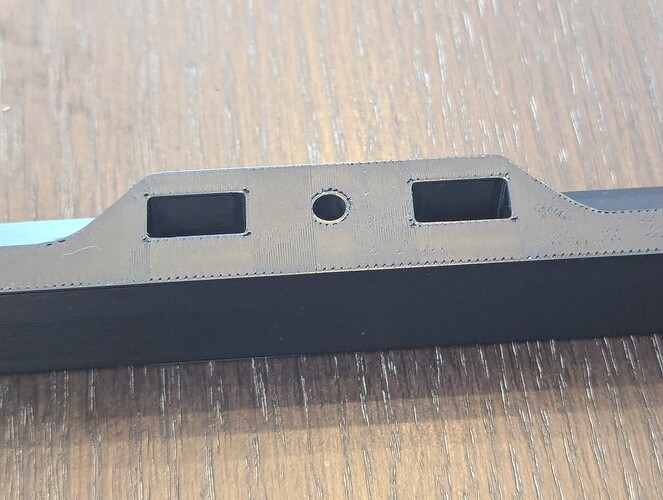

Had results so beautiful, I had to share. Top is with the settings I just posted, bottom took forever had at 30mm/s and 0.12mm line spacing. For the large flat surfaces, top killed it. The smaller surfaces look better on the bottom print.

For size reference, the top piece from corner to the furthest point is about 11.2"

Edit: Stock 0.4mm nozzle, Polymaker ABS - Black, Default temps, default layer heights. 5 top/5 bottom shells, 4 wall loops.