So my brand new X1C arrived on Friday and so far I’ve put about 20 hours in to it. Unfortunately I’m a little disappointed at the moment and I just wanted a reality check from those in the know.

From the first print there has been quite a lot of chatter and loud vibrations, I knew it was going to be loud but these seemed a little off. So I followed the wiki and cleaned everything just to make sure.

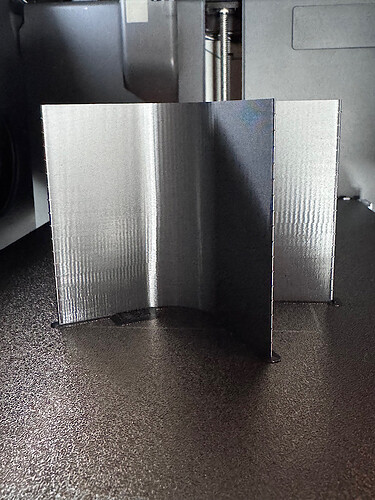

Then today I printed a poop chute in silk pla, as that was the best colour match I had, and the banding was absolutely shocking. It’s so bad you can actually feel the ridges.

I then followed the wiki again to adjust the belt tension, etc. I then printed the standard VFA test in orca slicer to see if it had made a difference. I used the standard esun pla+ profile in the slicer.

I then printed the Bambu test cube in Bambu studio using the same basic esun pla+ profile.

My question is, is this the typical quality I can expect from the X1C?

I think the retensioning of the belts may have helped with the chatter, but the banding is worse than my Ender 3 S1. The printer is lovely, I like the form factor and the speed, but I must confess to expecting more for my £1,100. I thought I would check with the community before raising a ticket. I did read a lot of the banding thread, but I stupidly thought BL might have gotten a grasp of things as the activity had lessoned somewhat. Cheers for any opinions.

I would say “no” not expected. The banding is also very regularly spaced. I think you’ve got a bad pulley or maybe a booger stuck to one of the belts.

Did you print the cube in the center of the build plate? If so, put 5 on the plate, one in the center and one in each corner and see if they’re different.

6 Likes

That is worse than normal.

I’d suggest putting in a ticket immediately to make sure you raise the issue in the warranty period.

Since support takes some time, you can work with the community in parallel.

I expect you ran through the entire recommended maintenance (including carbon rod cleaning)? I’d do that together with the belt tensioning again but to do manual head movement many, many times. Perhaps you can hear something from the belts?

And then to follow up on @RocketSled suggestion.

2 Likes

Well I’ve raised a ticket, so let’s see how long and painful this is going to be.

I forgot to mention that I did the whole belt tension thing twice, carbon rod cleaning, etc, I even checked the bed Z level procedure someone suggested in the long thread as well. I’m certainly no expert but the grounding I received from my Ender experience helped a lot.

The poop chute was almost the whole width of the plate and the banding is consistent across all of it. If you look closely at the front ramp part to can see how the X & Y banding interact to give some crazy zig-zag pattern. Very disappointing for such an expensive machine. I printed one of the 3Dsets Land Rover models on my Ender 3 S1 pro and although it was slow the quality was surprisingly very good. I’d happily put these two printers against each other and the Ender so far would have the lead in quality, it would just take 4 times as long to get there.

I’m assuming I’ll be offered a refund or exchange, as I’m in the UK we have 14 days distance selling rights, and at the moment I’m more inclined to go the refund route.

1 Like

With such severe VFA’s and still in the refund period, taking that route does make the most also imho.

Unfortunate, as it can take a while, but the most straightforward.

PS: Within the refund period, you should be able to demand a replacement in the ticket. In my experience, it helps to say it straight rather than running the verification gauntlet. Also, you may want to link the forum threads in the ticket.

1 Like

I’ve read the returns policy and that does seem to be an option. However it also says I have to return it first before they will issue a replacement, unless I want to pay out a further £1,100 and unfortunately this is not possible, so if it’s going back I might just get the refund anyway. I don’t know if I could take receiving another faulty one. They certainly can’t guarantee that I will get a working one, and it’s left a bit of a sour taste at the moment. I had high expectations and I’ll spend more time checking the new one works correctly rather than just sending stuff to print. This was the main reason for going the Bambu route, I spent time tinkering with the Ender and being able to view something on my phone and just send it to print was a welcome change.

Thanks for the advice in being clear and stating what I want, that could be useful.

1 Like

I did have to go through the replacement loop due to a defective LIDAR and blown mainboard. Since I did not have the original box anymore, I took the payment advance method. It worked out well for me. Took around 5-6 weeks from payment to reimbursement (but I took 1 week of testing before stating that the printer is OK and I’d like my payment back).

1 Like

Well support contacted me on Tuesday night. They said they don’t support Orca Slicer so the tests I’d ran in there wouldn’t count. They didn’t mention all the other tests I’d already completed in Bambu Studio, but hey ho. They asked me to run a test print and a test gcode. The test gcode was very aggressive, basically running a vibration test at different points on the x axis, it was literally shaking the unit it was on. Not the best when I’d started it after midnight, but ultimately that was my fault.

The test print ran fine and took a little over an hour to print. It was probably the fastest print I’ve seen so far. Looking in Bambu Studio it was consistently around 250mm/s. It was nice to watch how fast they can print. I think the idea was that running this fast the VFA’s would not be visible so they could possibly then say everything is working as it should. It’s much easier to see on video than in pictures, but unfortunately on this occasion their potentially crafty ploy seems to have failed.

Even printing this fast and thus making the PLA go matt, you can still see the problems I’m having.

Not completely obvious in the pictures but there’s some real funky texture going on where the VFA’s are crossing with the diagonal ringing. Ignore the moire effect that’s from the camera, as the layer lines are very consistent

The diagonal ringing is on all 3 print towers and all the corners, some obviously worse than others depending on whether the defect is on the outside or the inside.

I’m just waiting for them to come back to me with a solution/plan.

Unless someone can show me (images would be nice  ) that mine is a very unusual case and unlikely to happen again, I think I’ve going to ask for a refund. My logic is, I’ve seen numerous prints posted on sites where people are asking for help about something or other, but no one mentions the completely obvious VFA’s on their print. So maybe I’m more sensitive to them and a core XY that uses this belt arrangement is not for me.

) that mine is a very unusual case and unlikely to happen again, I think I’ve going to ask for a refund. My logic is, I’ve seen numerous prints posted on sites where people are asking for help about something or other, but no one mentions the completely obvious VFA’s on their print. So maybe I’m more sensitive to them and a core XY that uses this belt arrangement is not for me.  It’s really disappointing as I saw this printer 2 years ago and thought how good it looked and I really wanted it, but I just said to myself that I couldn’t spend that much on a printer. I’ve waited until now and finally convinced myself to get one and things just haven’t worked as I thought they would. I’m adding this so people don’t think I’m just some kind of troll trying to cause trouble on the BL forum. I’m not even sure if anyone will find this remotely interesting.

It’s really disappointing as I saw this printer 2 years ago and thought how good it looked and I really wanted it, but I just said to myself that I couldn’t spend that much on a printer. I’ve waited until now and finally convinced myself to get one and things just haven’t worked as I thought they would. I’m adding this so people don’t think I’m just some kind of troll trying to cause trouble on the BL forum. I’m not even sure if anyone will find this remotely interesting.

I’m not sure if anyone is actually interested in this or not, but I thought I’d give a further update.

BL have confirmed they think it has a faulty accelerometer and offered a replacement board or a replacement printer (7 business days and 20 business days respectively). They think the problem is only on the speed changes at the edges of their test print and do not acknowledge the VFA’s at all.

Personally I don’t think that is acceptable on an £1,100 printer (my order was actually £1,300 by the time I’d order some spares, etc.) so I’ve requested a full refund instead. I’m not expecting to see the money back in my account until the new year, especially with how long things are taking (2 weeks just to have it picked up  ) which means I’ve missed out on the BF sales, but hopefully by then there’ll be new ones.

) which means I’ve missed out on the BF sales, but hopefully by then there’ll be new ones.

Such a disappointment as mostly it is very good. This was Elegoo Rapid PETG just using the default generic HF PETG profile.

3 Likes