Very high probability of an ID10T issue here, but I need some suggestions on things to check/possible causes.

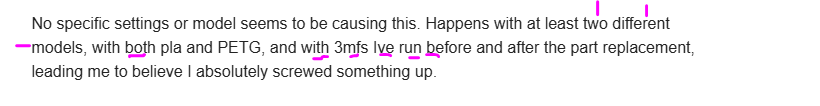

Like an idiot, I printed a tall skinny model using gyroid infill, the excessive wiggle/vibration caused the model to fall over resulting in a blob of not quite death.

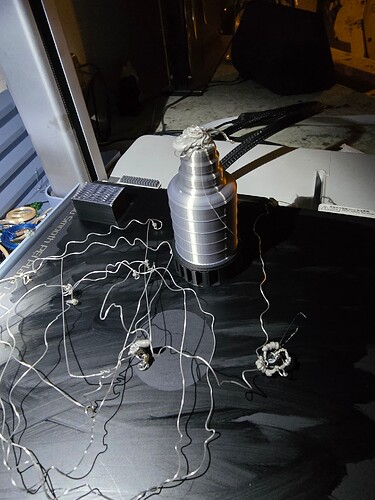

Removed the blob, everything ok, but because I am who I am, I couldn’t leave well enough alone and ended up breaking the wires going to the hot end heating element. No big deal, I had a spare on hand and I replaced it.

However, now the nozzle is hitting prints pretty consistently, which it was not doing before I replaced the heating element.

I’m not quite sure how I screwed that up seeing as there are only 3 holes for the 3 screws…

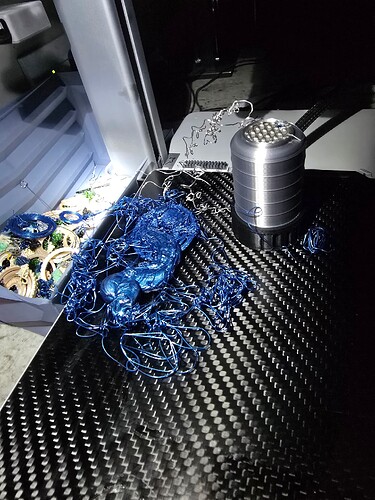

I raised the zhop to .5 then to .8, and changed it to normal, then slope, then spiral or whatever it’s called. It definitely hits less than it did, but still hits. The change in zhop type doesn’t seem to have much change.

I just want to go back to the reliable more or less set it and forget it situation I was in beforehand.

How did I manage to make things worse?!

Side note that Im absolutely too lazy to look up, what style zhop is “best”?

A1 using wham bam carbon fiber plate. Using magigio. Filament dried and subsequently printed from within a Sunlu s4.

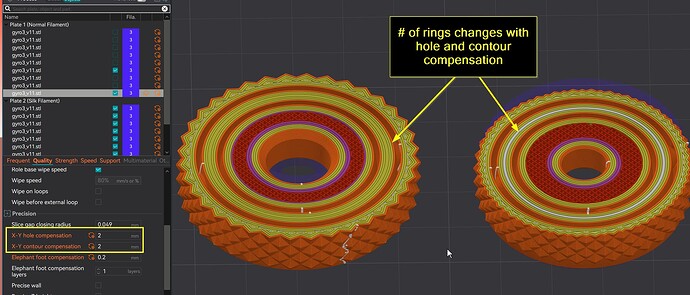

No specific settings or model seems to be causing this. Happens with at least two different models, with both pla and PETG, and with 3mfs Ive run before and after the part replacement, leading me to believe I absolutely screwed something up.