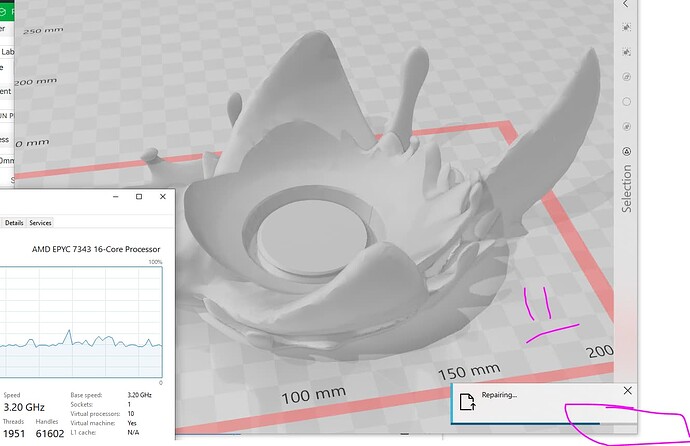

yes when you open alt projects and they are for say the X1 or something, all you do (if the model isn’t giant I mean to fit on our smaller printers) is change the machine type - the studio is smart enough to do everything between it’s own brand of machines.

It will prompt as you see to use the settings or discard them for the defaults but it’s not quite clear on that sentence when it asks. but that is what it means and correct, I didn’t change very much trying to preserve your settings.

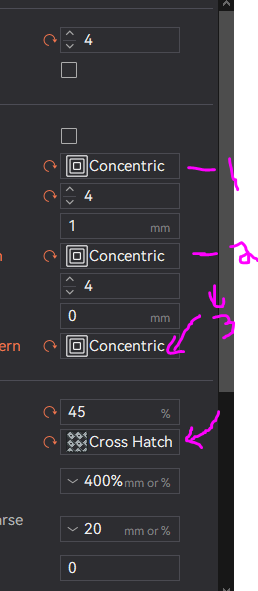

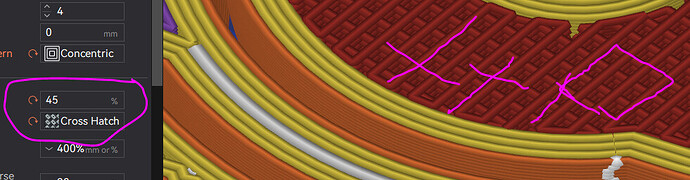

I noticed my concentric infill was a moot point as for whatever reason it refuses to draw in a circle inside, but on larger models it does work. Usually with the new cross hatch or gyroid (safest) infill you don’t need past 25% if even that…15% the default is already too much in most cases I start with 10 and see from there. Obviously changing this changes the properties of the print as well.

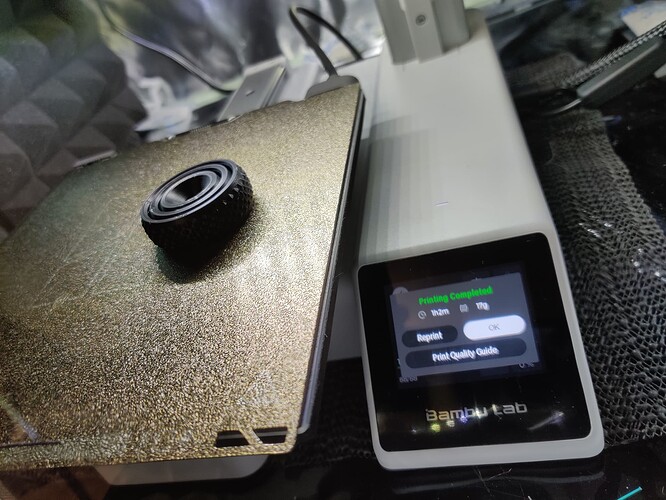

your fidget spinner I would honestly try once solid like i made IT SPINS FOREVER omg thanks for sharing that my kids already made it vanish and are asking for more. the extra 100% solid weight makes it a real nice toy there.

As for objects you will use both, all the time, depends what you are doing. just go slowly at first. The default stuff is actually so good that most peoples “tinkering” settings are worst.

If you aren’t sure just use the default 02 Layer height profile, chances are it will print just fine.

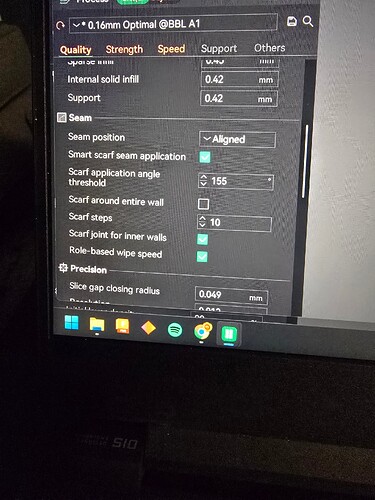

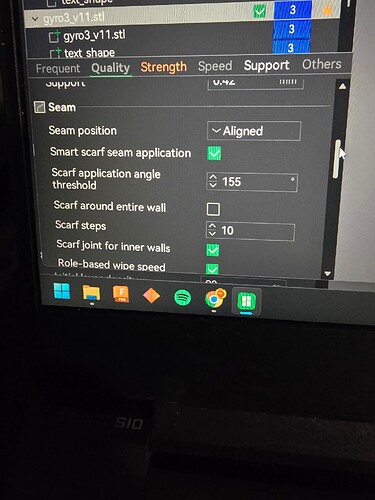

As to options and where - there are options hidden from you and you need to press the slider option “advanced” or the “dev mode” in the bottom of the settings panel. then extra stuff shows up.

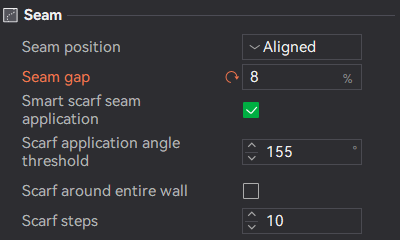

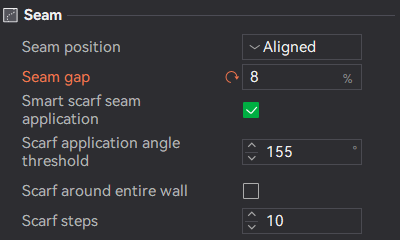

Scarf is something I’ve been testing and I personally find 8% down from the 15% is the sweet spot, going lower somehow adds small holes due to the speed of the print, maybe reducing this will help but i don’t give a sh*t there will always be a seam.

note there is a search magnifying glass to look stuff up in the settings if you can’t find it.

And as to what it is - a debate basically. and how good your printers are. The gist is here

But don’t, you can’t get invisible so hence the debate. Some have gotten close but it all depends on a slew of things and literally never changing them. on FDM you get a seam. I find personally 8% is about the sweet spot for regular speed printing. If you aren’t sure just don’t touch it.

A lot of what we are talking about is intermediate to more advanced 3d print learning. Scarfing and seaming is generally when you are so bored and done everything and just want to squeeze that lemon a bit more meh.

As people here in my house want more spinners you get lucky tonight haha, Also silk is a bit tricky, I made a profile i will print tomorrow in silk myself, so all you need (in theory it will keep my settings) to do is change the printer to your A1 and change nothing else, send it and 8h later your 9 spinners will come out. BUT i don’t think 016 is needed…making this one change with this same file to 02 layer height will shave off 1 hour. But legit it takes 45min per spinner normally so the 8h for silk is very damn fast for solids!

You can try as-is then with this one change to compare the two as you seem to be manufacturing these so quality might be important to you. I’ll post back when i get a set done to let you know.

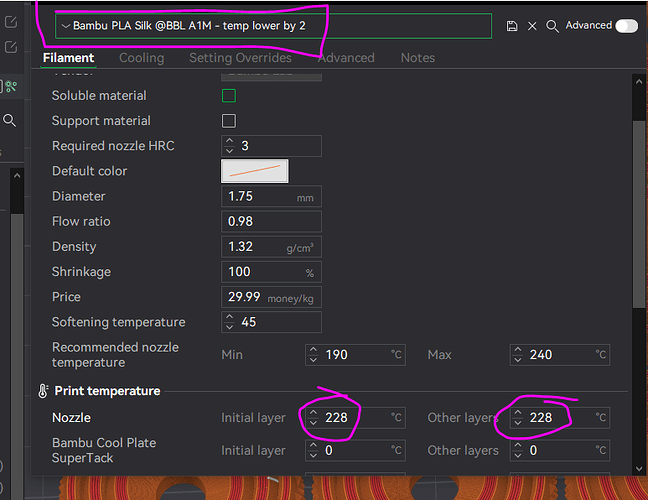

Note this is a special silk setting slice and it will suck using it for say pla+ or matte. there are special temp and speed settings you need to use for silk to get it super bright and shiny. You can however use it on other silk junk, that will make it very nice! You can go as high as 235 for silk but it makes it very stringy depending on brand and quality, i found the sweet spot to be 228 forced across the print vs shine vs 0 stringing vs speeds. it’s all a fine balance.

IF the settings for whatever reason do not carry over this edit of the silk filament TO these temps and resaving to your own to select should match mine to recreate.

Project Spinners 8h 016LHO SILK.3mf (551.0 KB)

EDIT: was it from averagejoe model this spinner on makerworld? If so I can upload the profile directly there for everyone in silk making it easier as then you can just hit print from the app. Let me know I’ll se it up tomorrow for single/plate if it’s him over there.