So i ended up upgrading from old Orca Slicer to be able to use the Supertack plate.

I previously were able to print perfect prints with Engineering plates with glue, Tex PEI, Cool plates with glue

But after I got the Supertack, i just can’t get any PRINTS to stick!

Don’t get me wrong, I am perfectly able to print CALIBRATION PRINT MODELS, anywere on the supertack, but as soon as I try to print a model, it just refuse to stick properly, and behaves like it is clogged, or like there are fingerprints, when there is not.

I wash the supertack in soap water, make sure no fingerprints, even tried isopropanol on it to be sure.

The problem affects both PETG and PLA, and then filament i have already perfectly calibrated the K-values and Flow-values for.

I have done perfect cold pulls of brand new nozzles, I have tried 0.2 nozzles, and 0.4 nozzles and same problem appear on both.

I have tested with both Bambu Studio as well as Orca Slicer, and the same problem happens when i print from both.

Calibrations work perfectly, but real prints, fail for the exact same filaments.

Settings that the supertack prints out fine in calibration, just does not stick for real prints.

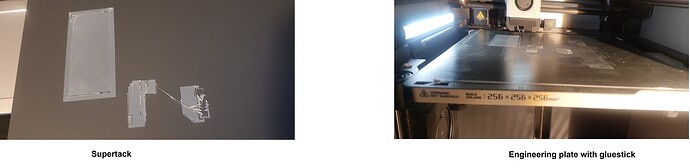

Below is a screenshot of supertack result versus Engineering plate with gluestick results.

And yes, the filament has been properly dryed for 24 hours and is at less than 10% moisture.

PETG, perfectly dryed and calibrated, 260 degrees calibrated, 70 deg bed on both engineering and supertack

I am at a loss now, as to why i can calibrate using Supertack, but no chance i can PRINT with it.

When I initiate real prints, the test lines go down perfectly, and then after the last line it is almost like it adjust z-height so filament barely touch the plate.

HELP?

*PS: Anyone here got Supertack, X1c and IS able to print on this buildplate, and can share their standard 0.2 and 0.4 nozzle machine codes so i can compare? Totally standard nozzle configurations, no changes. *

*That way I can inspect the gcodes for differences. *

Because if this was a problem with the hardware, it should not be able to print the calibrations either.