That’s the question. They kind of addressed it in their post above when they mentioned heat from drying the filament was possibly part of the issue but didn’t say if they tested the new method to see how it does or not. I can see tape adhesive bits making to the extruder and other contact points possibly being an issue. Ever since this became an issue I babysit my ends of spools. I don’t want any chance for gumming things up but am lucky I can. Print farm folks might not be so lucky.

They should put the tape on the inside of the spool. This would give us the option of cutting the filament and removing the tape.

To tape on the inside, the filament end first has to be threaded through to the inside, which would make tape unnecessary.

@SupportAssistant I have a potential solution for this. Add a software feature allowing users to set a swap parameter for the AMS.

For example. I want the AMS to swap from slot 1 to slot 2 at 5% remaining on the bambu roll that is AMS slot1.

Additionally, add the option for the user to manually specify how much filament is remaining on the spool in either percentage, grams or meter. This will allow the user to correct incorrect AMS readings from the RFID tag.

This will allow users to set their own safety margins and assist in avoiding the tape issue.

Thank you for your feedback.

Please note that the tape issue has happened for a small number of spools in a batch. The issue has been solved as described in the previous post, with the tape being correctly applied.

Just out of curiosity, does anyone know of any other filament manufacturer that uses tape?

I don’t really agree. There are posts on reddit with the proper tape application where it is still happening.

And the tape you use leaves no residue on the filament even after heating in a drying oven?

I think that’s the remaining question. I can see how the proper arrangement can make it where the tape remains with the cardboard hub, but bits of adhesive stuck on the filament can gum up the mechanics and decompose in the extruder.

I’ve seen cases where the RFID tag doesn’t match the filament, and I’ve seen cases where the RGB values are different for the same filament which prevents the auto-switching from working. I’ve also seen where the color on 2 boxes of purple don’t match, but the filament appears to match - one had a dark purple circle and the other a lighter purple circle.

I’ve also seen the tape issue but not recently. In my case I was lucky and the AMS didn’t rip the tape off so I simply cut the filament before the tape and let runout detection do its thing.

All that said, I still buy Bambu filament…

I’ve been having a mixed time with this tape issue. I’ve had the tape release fine on several rolls, but I’ve also had several instances where the tape came off and jammed the AMS up. Very frustrating. I’ve been printing mostly with PETG-HF, and it’s been an issue on all of them. You guys that know me too, know how many big things I’ve been printing lately, so a lot of having to switch rolls.

Yeah, so overall though, I haven’t had too many issues, but when it is an issue it’s an ISSSUE. I’ve had a couple of prints fail because of that, and that can be spendy. When you’re a day into a print, a roll into a print, then the AMS jams, and you’re trying to fix it, but yeah.

Were they the new way Bambu is telling us they have switched to or the old way where someone just stuck a wad of tape over the filament?

I guess I hadn’t entirely taken notice with the previous ones. It did happen again though. It pulled the tape off then jammed up in the AMS. I was able to get it unjammed and snipped the end. Here’s some photos

If only that tape had the same holding power as me with money, it’d be a non issue, it’d never be able to hold onto that filament.

I can’t say for certain but that looks like the new way @SupportAssistant said they are now taping spools by the photos in this linked post:

If it is, the problem may not be solved and folks should stay vigilant. For those still having issues, they provided a link to report in that same post.

@Josh-3D - I’m going to guess that spool was dried too where it was exposed to some heat? Any chance you know the serial number of the spool? They want that if people report further problems.

Just had this happen to me on two separate spools of PETG-HF that I just bought last week. I actually had to disassemble the AMS mid-print to clear the jam. Bambulab, this is not acceptable!

I’ve just emptied a PETG-HF and a roll of PLA Basic and both had tape.

The PLA was finished on a Sovol SV02 and it sounded like the machine had broken when the tape was finally ripped of the cardboard centre

Try this as a temp solution, the tape resistance should actuate the device the same way

https://www.printables.com/model/54031-automatic-filament-cutter

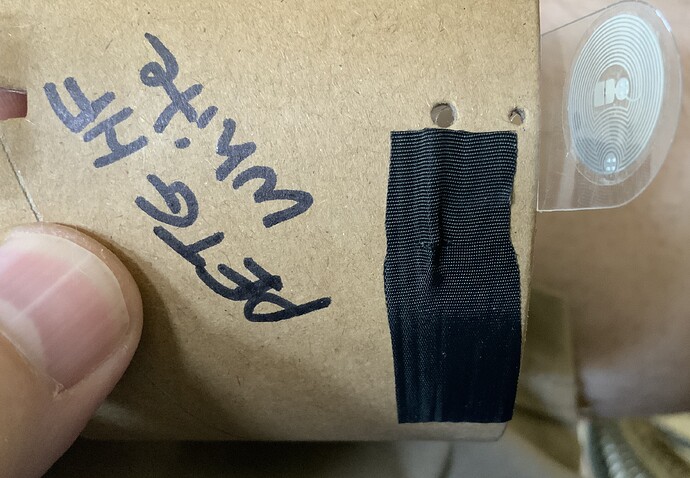

Encountered what looks like the new taping method at the end of a spool of white PETG HF.

Instead of letting the AMS try to pull it free, I snipped the filament near where it disappeared under the tape and decided to have a look-see after replacing the spool.

I tried pulling the little tail of filament with my fingers to see if it would pull free and it did not. Then I grabbed some pliers to pull the little tail free and it did come free but only after pulling pretty hard.

I don’t know how hard the AMS can pull on a filament strand but it seemed to take a lot of pull to get it to come free. Worse, it was gummy with tape adhesive residue on the filament surface where it had been captured under the tape.

Just my opinion but I don’t trust the filament to always pull free of the tape with that kind of grip it has, and I’m not a fan of the adhesive residue getting pulled through the filament path and into the extruder.

This spool was dried with heat at 55C so that could have helped the bond and helped transfer adhesive to the filament. But I don’t trust this new filament attachment method to cleanly finish off a spool and the adhesive doesn’t seem to stay on the tape.

Interesting to know. I was always dubious about the tape not leaving any glue on the filament, especially after it’s been dried…

It does look like the new tape method that was show above by @SupportAssistant on Aug 21st.

Looks like it wasn’t resolved and they still have issues…

To be fair, I did not let the AMS even try to pull the filament free. It might have plenty of pull to do that. I didn’t give it a chance to prove itself and it’s the only roll I’ve hit so far with this tape anchor method.

But the adhesive residue on the filament tail was real. Whether or not that is actually an issue for the filament path and extruder is another thing. The path and extruder might not care.

Really curious what others notice as they hit end of spool with this tape method.

Until there’s more information, I’ll be cutting the filament free and trying not to let the tails go through the filament path and extruder, though.

I’ve had this issue on a brand new spool of PETG-HF I purchased last week.

It uses the new application method and the AMS tore off the tape and a piece of cardboard with the filament.

Fortunately for me the tape and cardboard got stuck on top of the funnel and didn’t get dragged through the whole AMS.

This ruined an 18 hour print and over half of a spool of PETG at 98% completion of the print.

So about 12 Euro worth of filament (plus energy cost and wear/depreciation) due to less than a cent’s worth of black adhesive tape