I was able to changeout the left nozzle, but the right nozzle seems totally stuck. No filament currently loaded. Original, factory installed nozzle3 that I have never removed.

Any recommendations?

I pulled a ticket for it, but I’d rather not wait the 1 week minimum for a reply of any kind.

Anyone else ever faced this but found a way to solve it? How?

It is possible there is some filament stuck above the nozzle in the path through the print head itself.

I am assuming you have initiated the filament cut process, automatically or manually…

I do not have the H2D, but it uses the same nozzle as the A series, one of a many printers I do have.

- Try heating the nozzle to 250ºC

- Wait a few minutes (maybe 5)

- Manually press the right filament cutter bar

- Tell the printer to lower the temp back to 0ºC

- Do NOT wait for the nozzle to cool down

- Using tools (NOT HANDS), unclip the spring that locks it into place

- Carefully grip the front edges of the heatsink portion with pliers and pull towards you, using a small amount of force to twist it so one side moves first

- It is held in by magnets, the twist is to assist that

If you feel like you are dragging it, stop.

The nozzle should release. I have had this myself.

If there is resistance, there is something stopping the the nozzle separating from the hot end, that will need to be determined before trying again.

The H2D nozzles are very similar to the A series, these are deigned to be easier to remove than those of the P and X series.

They are held on by a magnet and kept in place by a clip, my first time removing one, it felt like it was glued on. The pliers made all the difference.

I have not often needed to use pliers again, but when there is filament still poking up into the rest of the head - it causes problems.

5 Likes

If you don’t have an H2D then why are you commenting??? You’re just adding to the confusion for an easy fix.

OP: You have to select the right nozzle on the LCD screen and move the filament cover lever to the left so it can move out of the way. Then you can swap out the right side just as easy as the left.

6 Likes

You can’t help yourself can you?

Trolling all day long.

If you do not have anything constructive to say, why bother?

7 Likes

Trolling??? I’m not the one telling the guy to take pliers to his $2-3k printer! I’m all for helping out, but at least know what you are talking about.

Trolling… Constructive??? The guy can damage his printer and it would be your fault. SMH…

1 Like

I started off clearly stating I do not have one.

You have been following me around, trolling as you go.

Most of your reactions are negative to all others here. You are new to the forum, yet you are being a #$%^ to everyone.

The self-imposed superiority is oozing from you.

15 of your 26 reactions are negative, that is 58% of those contributions.

Yet, despite it being the definition of troll behaviour, you are confused as to what you are doing.

7 Likes

I tap the tip of the nozzle from the rear. Mine get stuck every time.

2 Likes

Does that make you feel better? Like I said, you gave out bad advice on a printer you don’t even own potentially having someone damage their printer… I called you out on it and then gave the proper solution (likely).

2 Likes

What did you do?

Did you go back and remove all your negative reactions and unnecessarily unhelpful content?

There are ways to say things, but you focus on being negative, rather than helpful.

What was wrong with giving what you believe is the (likely as you put it) answer and leaving it at that?

I assumed that @NeverDie would have known about the locked bar, if that is even related, for two reasons:

- He is smart, as he has repeatedly shown on the forum.

- He didn’t start by saying “I got this today”; from memory, he has had it for a while.

Respect others while you are on the community forum.

You have only been here for three weeks. Yet, most of your contributions belittle others or dismiss their experiences because you have not had any issues, making their experiences seem invalid.

This isn’t your forum, and it isn’t mine; it is for all of us.

I hope you go on to be a more productive forum member.

3 Likes

Are you done yet? Nice way of deflecting your bad advice… You’d rather whine at me than take accountability for giving wrong information on a printer you don’t even own. I have stopped apologizing for my bluntness a long time ago and I’m done with you.

@NeverDie I hope you got the nozzle out after moving the nozzle cover lever, if that’s what the issue is.

4 Likes

Solid advice, but I did that already, prior to posting.

2 Likes

Worth trying. What are you tapping it with?

You can try doing a cold pull if it is that little piece of filament preventing it from coming out. Otherwise a bit of heat if it is some loose filament that fused it to the heater block.

1 Like

I’ll give it a try at 250C, as you suggest. I earlier tried something similar at 220C, but I’ll see if the extra heat help may help.

Is it OK to remove it while hot? I have special BBQ gloves that would avoid my getting burned. They’re clean.

Ya its fine… I actually have a silicone mould beside the printer that I put hot nozzles into after removal so they dont burn anything.

2 Likes

I just had this happen to me yesterday on the right nozzle. To get it out instead of pulling from the bottom of the tip I slightly pulled from the top out towards me. It got loose and then I could pull the bottom out easily.

1 Like

Yes the right one is always a bit harder to remove as it does not move up and down. Usually its that little length of filament in the hot end preventing it coming out easy, a bit of fiddling is usually necessary.

2 Likes

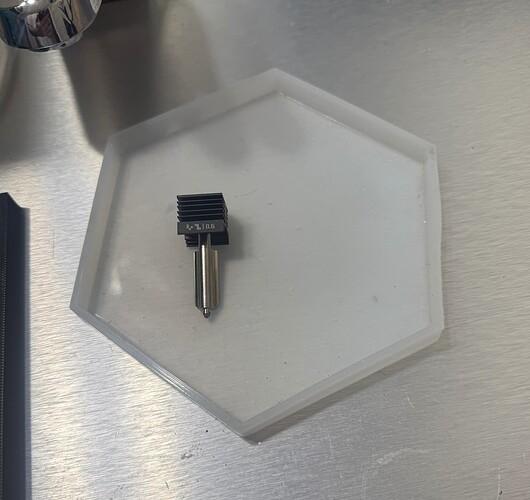

It worked!

Heated it to 260C and then pulled it off with the high temperature glove.

I had earlier tried to remove it with needle nose pliers, but only succeeding in bending the heatsink fins.

4 Likes

Probably a good idea to heat it up and clean it with a bronze or silicone brush to remove all the molten filament.

1 Like