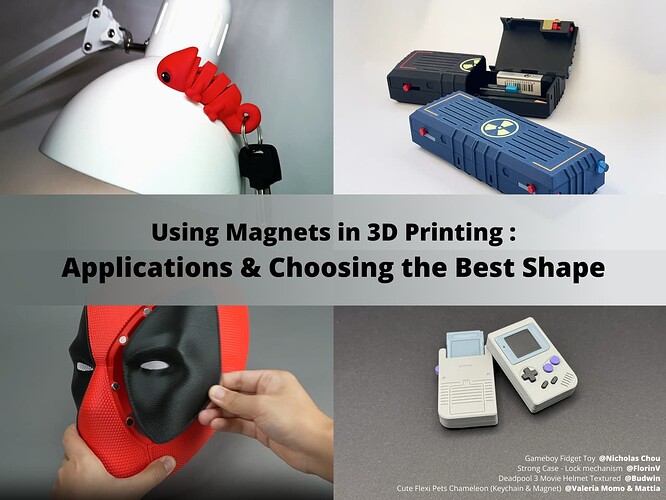

Magnets can hold things together or push them apart without any physical connection. This makes them incredibly versatile for 3D printing. What cool things can we do with magnets? Here are some examples:

Why Use Magnets in 3D Printing?

- Stick to Metal Surfaces: Magnets let you attach your 3D-printed creations to things like refrigerators, lamps, or metal furniture. For example, a cute chameleon keychain can double as a fridge magnet.

Cute Flexi Pets Chameleon (Keychain & Magnet) by Valeria Momo & Mattia.

- Make Self-Resetting Parts: Use magnets that repel each other to make moving parts (like a lever or button) automatically return to their starting position.

Strong Case - Lock mechanism by FlorinV.

- Keep Things Aligned: Magnets can hold parts of a fidget toy or stress-relief gadget in place, giving a smooth, satisfying push-pull feel.

Gameboy Fidget Toy by Nicholas Chou.

- Enable Quick Assembly: Magnets make it easy to snap parts together or take them apart, like swapping pieces of a costume mask.

Deadpool 3 Movie Helmet Textured by Budwin

There are so many types of magnets! While round magnets are the most commonly used, other shapes each have their own specific use cases. Here’s a quick guide to help you choose the right one for your needs:

Which Shapes of Magnet Should You Use?

- Round Magnets : The Most Widely Used Shape

Round magnets are highly versatile. Their affordability and regular form make them the most commonly used type of magnet, suitable for almost any application.

Strong Reversible Mini Ratchet Driver by Kwiatens

- Rectangular Magnets: When You Need Strong Adhesion

Rectangular magnets are able to achieve stronger magnetic force in tighter spaces. These are suitable for long-edges that need to be attached (e.g., chessboard edges).

Rollable chess board, Print in place! by Felix, showcasing rectangular magnets used for stronger adhesion.

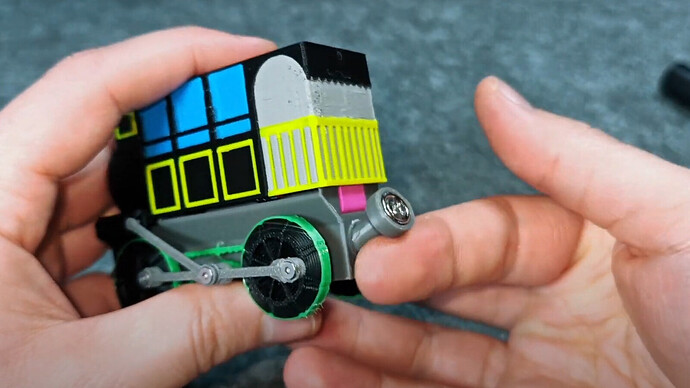

- Ring Magnets: When a Part Needs to Pass Through the Magnet

A ring-shaped magnet has a hole in the center, allowing screws, shafts, and other components to pass through. It has special uses such as connecting toy train cars. Sometimes, they can also be slipped over a shaft to function as a magnetic spring.

Retractable Ballpoint Pen by wuguigui

- Disc Countersunk Hole Magnets:Reduce Installation Difficulty and Secure with Screws

Thanks to their shape, Disc countersunk hole magnets make it easy to tell the poles apart. Additionally, they can be screwed in place with flathead screws for a secure fit, which is why they’re often used in household models.

Electric Modular Steam Train - Brio/Lillabo by Starting Energy YT

- We are grateful to @MaKim for helpful feedback on earlier drafts of this guide.

Upcoming chapters about magnets in 3D printing

-

Using Magnets in 3D Printing 3: Installation Issues & How to Avoid Them

-

Using Magnets in 3D Printing 4: Ensuring Even Installation