This was a day one issue. I tried reaching bambu labs support for a return/exchange. That was in February IIRC, I still haven’t heard a single word from them. I’ve reached out at least a dozen times.

That is an odd and understandably frustration issue. Wish I could provide a solution but I don’t know what else to suggest.

So even with something like a regular benchy it will come loose before it finishes?

Also, I know the P1S is enclosed but what is the ambient temp in the room?

Yes, every print. Without exception, fails unless I have a MASSIVE brim (20mm+) or I can sometimes make it work with magigoo. Has been like this from day one.

Room temp is between 69 and 72F with around 40% humidity.

Keep in mind, I don’t have this issue on my Creality printers using the same filaments. I don’t have this issue with other Bambu printers that have been brought into my home either (even when they use my build plates). Just my printer. I’ve even gone so far as to have my buddy who works as a repair tech for Lulzbot come over and see if he can figure out what’s going on. No luck.

I received my P1S on March 3 and within 7 days requested to return it. I’ve sent multiple requests since then (at least a dozen) and have never heard back from Bambu. Not once.

Needless to say I will not be buying another, not because I got a lemon (it happens) but because they simply do not care.

Next step I guess is buying a few build plates. I’m looking at the Biqu Cryogrip and Cryogrip Pro build plates as they are supposed to work really well… and they aren’t crazy expensive. If that doesn’t work… I think I’m just going to put it out of its misery with some tannerite and a lapua round.

Have you checked your buildplate temperature? I don’t mean from the software side! It looks more like the buildplate is not being heated evenly. maybe the heater is broken. maybe you or an friend have an thermal imaging camera or cheap laser thermometer.

You by chance know someone with a temperature gun? Might be worth shooting the build plate and the nozzle confirm the temperatures are correct…

When you wash your build plate, you are using a nylon bristle handheld scrub brush?. The nylon brush won’t hurt the plate because bristles are softer than coating. It is effective though in getting down into that texture. Scrub it like you burned a frying pan. Don’t use those microfiber cloth. Especially if you are just pulling them out of a pack from Walmart or AutoZone.Those rags have who knows what applied to them.Once you’ve scrubbed plate and hold it so edge is touching sink, water should bead up and run off the plate

Don’t spend money on build plates. If it won’t print Bambu PLA on the Bambu gold PEI plate thats just wasting money.

Serious about that. If you are using Bambu Lab PLA on that BAMBU Gold PEI Plate it 100% should print. If it isn’t you have not discovered the problem but the problem is not the plate

I have a temperature gun. It’s heating just fine and evenly.

Yes, I use a nylon brush, I’ve also used a scrub daddy scrubber when the brush didn’t work well enough.

I use microfiber cloths, but never fresh out of the bag. Always washed without fabric softener, never dried with bounce sheets. I’ve also tried paper towels, lint free cloths, etc… Water beads up just fine.

Like I’ve said, my build plates work on other machines. I’ve taken a plate that had a print failure on my device and put it on my brother in laws machine (without cleaning it in between) and it works perfectly. Every time.

I ordered the replacement plates out of frustration, if they don’t work I’ll send them back to Amazon. And I was 100% serious, if they don’t work I’m filling the p1s with tannerite and firing a .338 round into it. At least then I’ll get some enjoyment out of this piece of ■■■■.

Remove the glass first, you don’t want the shards everywhere, but I approve of a good tannerite release!

Have you considered selling it?

Let me tell you something about me, and my Bambu P1S #1 and Bambu Lab P1S #2.

Bought the P1S, and that thing went crazy after about 3 - 4 hours of actual printing time. Machine would not print. It had some sort of software bug and I went round and round with Tech Support and I pestered them every single day. Squeaky wheel gets the grease is true.

I have no idea what their service book says and how many hours they alot to a machine before calling it dead but for me, that took about 5 weeks of emails every single day and quite often 2 or 3 a day.

I have no idea what was wrong with that first printer and at a base level, I didn’t care. I bought a printer with the expectation, vigorously fostered by Bambu Labs, that it printed out of the box which was not true in my case. 5 weeks after my ticket went in, Bambu Lab said my printer was a DOA and lets swap it out.

Printer #2 is everything I hoped for and wanted when I stupidly bought a Creality ENDER-3 Pro.

You bought a printer with an expectation that it would print. As frustrating as it may be, you need to be the squeakiest wheel on Bambu Labs tech support backlog.

I think you can get your machine either fixed or replaced and will be happy with it but again…squeaky wheel

I tried talking to support. Numerous messages to them. Starting on day one and going for at least 45 days after I received it.

I’ve never once heard back from them. Not once.

And no, I won’t sell a defective product, especially not from a company that flat out will not respond to any of my messages. I’d much rather shoot it, post the video, and explain my story about why I blew it up and why I don’t recommend bambu labs.

Weirdly, PCTG (not petg) filament works every single time. I’ve burned through 6 or 7 rolls of it and it works perfectly. No warp, no lifting, it just worked. Why? I have no effing clue! But it prints perfectly, which is probably why I haven’t blown this thing up already. But PCTG isn’t cheap.

It’ll be blown up at a garbage dump on my personal property. Not worried about the glass.

Were you expecting an email, or do you login to support to get messages?

I realize you said you never heard anything from them. Extremely unusual.

I’ve dealt with anycubic support, to communicate, I have to login to their website and read their replies. Once, in about twenty replies, did anything ever come through email, inbox, junk folder or otherwise. This, even though their website said I’d get email notifications.

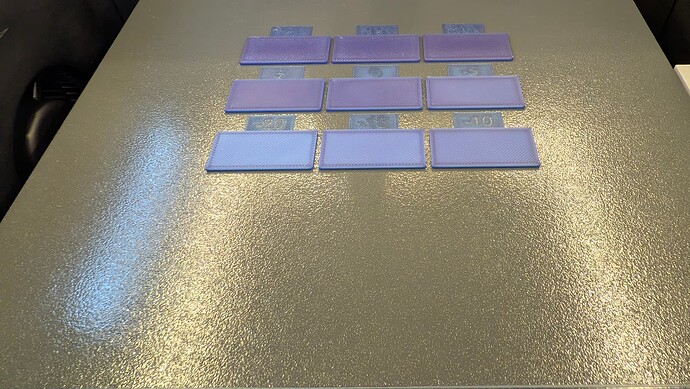

Yours

vs mine

Just ignore the ghost of the previous print. Can you tell the difference?

In your case, it would probably be better if you close the door and the top lid as well. But you may suffer the heat creep.

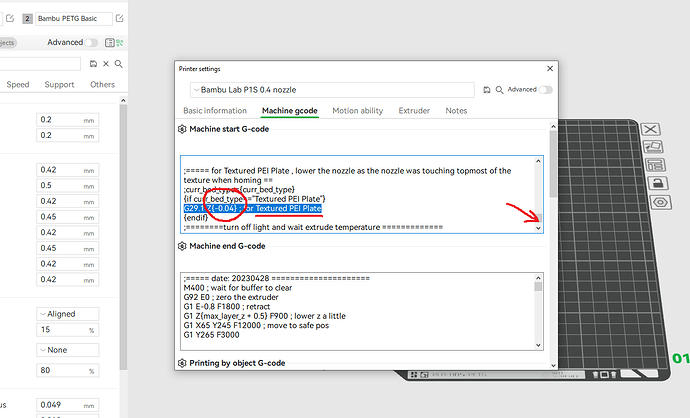

Solution is to move the nozzle closer to the bed. This code below is to offset the nozzle closer to the bed:

That’s how my prints look when they stick. With PCTG they look identical to what you posted. When my prints do stick (30 percent of the time) they look like that as well. I’ll try adjusting but I’m not holding my breath.

What bed and nozzle temps are you running? Starting with a known baseline, a dried bambu pla using the std pla profile, bed calibrate, 99% should work.

I was using the Gold PEI plate that comes with it, dried inland pla (I am out of bambu pla, I ended up using it in my Creality because it wouldn’t adhere to my P1S build plate).

Nozzle temp is 220C

Build plate temp is 35C

Everything has been calibrated and recalibrated dozens of times.

I just installed a Biqu Cryogrip build plate and for the first time ever completed the first step of the flow rate calibration for PLA without warping/losing adhesion.

35c for bed temp is too low for gold pei, 55-60c is standard PLA range. The original Cold plate bambu came out with runs that low ok though.

I’ve tried the entire range from 25C to 90C. I’m just using the built in flow calibration settings from Bambu.

Second round of calibration works. Apparently I need to use Biqu Cryogrip