I had issues with the filament buffer not having the right conductivity resistance. Bambu support walked me through what I needed to do diagnose it and they sent me a replacement. I was quite pleased with their support.

I too within a week of getting my new AMS had a stuck piece of filament hiding in the filament internal hub. I had some clear plastic coated antenna quidewire that was a very small diameter. I guess its 3mm or less, must be less. I cut a couple of piece off of different lengths, to give me "multiple versions of this tool: This stuff is perfect for shoving through ptfe tubing. Its stiff enough to not fold or bend, yet its flexible enough to make any curve. Highly recommend. Can’t locate the link to the kit on Amazon, sorry.

Hi, did anyone had any luck with loading the D20 or A70 TPUs into the A1?

I can not really feed it to the extruder properly, previously I have been using it on a cheap printer with direct extruder that it did surprisingly job with, however, it is too squishy to feed properly into A1 (both through the Tube and without it.)

Anyone had similar issues?

This fixed mine that failed to extrude outside the AMS casing on first day. I took it apart, manually ran filament through the 5 into 1 unit inside by winding it in with the gear after taking it apart and all good

It seems that choosing “unload” on the front panel Vs doing it in software upset mine. Thanks so much for the tip.

I had the same problem but i may have a fix, disconnect the ams tubes and putv your external back on, load the external till you see it come out your hotend, unload via your machine in your filament settings, once you have done that put your ams tubes back in and feed your fillament about inch away from ams into your machine, do not load these from here, find a simple 1 colour print and print it, this will then pull each filament through, had no problems doing it this way and i have had no problems since and swapped filaments every day, i hope this helps

In had updated the firmware to the 1.08.03? and then had a ‘maybe’ similar issue. i’ll link a video if i can. At first I tried downgrading, I’ve tried factory reset ![]()

I did end up getting a different issue, and I took hub apart and fixed the magnets.

This filament stop/retract/reload/till fail sucks.

It’s acting like its testing the taut-ness of the wire. If I give pressure to the spool it loads fine. It’s a lot like they inentionally stopped spools that I own. I dont have any bambu to test. My vendor didnt carry it, and I have to use vendor purchases.

Every slot does this, multiple vendors and filament types. Only in the AMS I have that I updated the firmware. My other unit doesnt do this, not updated. Smoeone suggested a motor issue, but that doesnt make since to why my finger can change the reaction.

Symptom:

Add pressure:

I have downgraded back to 1.07.03 and the AMS 6.4. Still happening.

I’ve cleaned everything.

- Canned air the tubes

- Took the Hub apart and fixed the magnets. checked the cogs/wheels

- checked the first stage loaders and the mechanisms seem fine.

I’m going to check the support shafts and drive wheel next, but this is rediculous … Occam’s razor… would suggest. My printer was working fine. That night I upgraded the firmware. Next morning then printer wouldnt work right.

ive had something like that with my brandew p1s comb. opened up and tried to doa test print and the filament would only get to the extruder gear and thats about it. i have a ticket out with bambu about this.

THIS!!! This solved my issue. AMS stopped feeding in the middle of a print. Loosened the 4 screws and it is fixed! Big thank #Godo

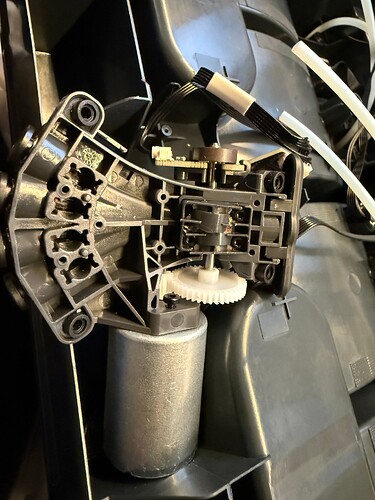

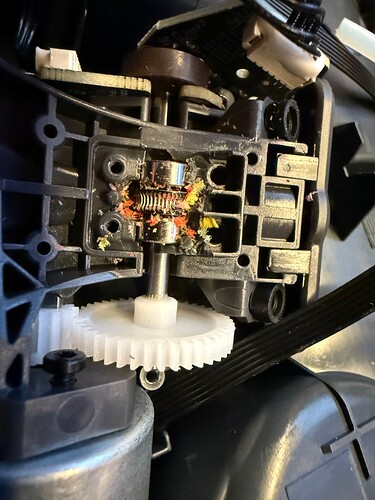

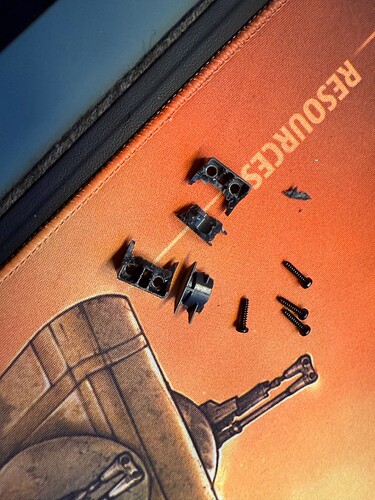

Thank you for starting this thread. My AMS has been acting up for a while now and had to assist it manually to feed the filament. Today I cracked it open cleaned all the feeders in front, but that did not help the issue. After reading on in this thread I cracked the AMS open again to check the rear motor and feeder. well that’s where the issue was. The cover that holds the feeder gear was damaged and the extruder wheel was just cracked on with filament debris. here is some pics. I guess I’ll be ordering the rear AMS assembly if its not covered under warranty (I had it for 6 months or so)

BTW, don’t take the whole assembly apart… LMAO

I am having about the same issue with my AMS lite and wanting to see if anyone can help me, not sure how long it will take for support to respond back but here is my issue:

I have a A1 Bambu Printer with the AMS Lite.

Tonight, I went to print and I got an error from the printer saying that my AMS could not load filament. The printer game me steps to take and I did the following:

- Made sure there were no broken off filament parts in the tube.

- Make sure the tubes were good, and plugged in the way they should be.

- Unplugged the printer and tried to print again, with same error.

- Reloaded the filament and once I got the filament just inside the AMS feeding hole, the gears DID TURN and feed the filament halfway yup the tube as it should.

- Pushed the filament by hand in to the tube and did no0t feel any friction on the filament or any reason why the AMS could not feed the filament to the hot end.

- I replaced the nozzle on the Hotend.

- Uninstalled and reinstalled the Bambu software.

- Still having the same issue.

- The firmware is also updated to the most recent version.

Summary of the problem:

I put the filament in the opening hole and push the filament in till the AMS system starts feeding the filament in to the tube on it’s own, this does work.

When I start the print, the printer will do all the steps to start the print but then the error will come up and tell me the AMS could not load the filament. I can see that the gears are turning on the hot end, BUT the spool is not turning. The attachment that holds the spool on the AMS is also NOT turning. I also made sure the spool was all the way on the attachment and that the lights were also flashing on each filament port and they are.

The code I am getting is: 12FF-8003 002419

I got this fixed, it was a small piece of filament stuck in the neck where the 4 tubes are plugged in too. Here is the video that helped me.

I had a similar issue to Archer 032 the rear feeder gear was blocked.

I was running a 4 colour print, one of which was a multicolour filament.

The number of in an out iterations was high and the multicolour filament was being frayed on each use to the point where it disintegrated.

If you get a feed failure at this point i.e. the front feeders work initially and then start spin and no filament exits the AMS unit or you hear grinding or notice fraying on the filament this is the likely cause. My experience is that with multicolour filament is; that you need the best quality filament, use it on prints with only a low number of changes or where the usage is fairly high on each iteration.

Hi,

I’m having the same issue with AMS, I did few prints before using the AMS and it’s works fine but I’m keep on getting the error “cannot push filament to extruder”, I checked the extruder…there is no issue with that, no clogging or anything

Lightly used AMS and printer started having the feed error during a multiple color print. Did all the internet/forum/youtube checks for solutions. One post said the gears in the internal hub unit can get gummed up with filament debris and the check and clean that. So I opened up the AMS and unscrewed the four screws holding the really thin and small plastic plate housing for the bearings and gear, only to find it split in half. The pressure from the filament going through the hub unit caused it to flex out and not give enough pressure to grab and advance filament. Explains the grinding noises it made trying to feed.

Super glued it back together to finish print and until I can get a new $55 internal hub unit. This is a pretty obvious design flaw and point of failure.

OK, so here’s my variation on the AMS “unable to feed” issue. I’ve spent some time searching and reading but haven’t found anyone else having this particular problem, so here goes:

All four slots of my AMS work perfectly well feeding filament, right from the start until the spool is empty – if I were to run a print that long!

And, starting with a full or half spool, it will continue to start new print jobs with no problem feeding the filament.

But once the spool gets down to about 1/3 or less remaining, if I start a new print job, it will fail to feed the filament EVERY TIME. The angle from the filament to the input tube is much sharper once the filament gets low, and the spool is yanked forward rather than turning smoothly. The AMS isn’t trying to turn the spool forward at this point, it’s just yanking on the filament to feed it, and the spool comes forward and jams.

I have to open the AMS cover and manually turn the spool forward a half turn to give some slack on the filament, and then it will feed again properly. And will continue to feed properly to the end of the spool … unless I start a new print job, and then it will jam again on the initial load.

It happens on all four of the slots. Very frustrating. Anyone else getting this “1/3rd or less filament remaining unable to load” issue? Any ideas how to fix it?